Is t

he

piston engine concept the best for ever?

Why is it so difficult to substitute it?

The Quasiturbine systematic engine concept analysis gives answers...

Theory - Quasiturbine Concept

Quasiturbine Not a Vane Type

The vane-type pumps are known for their very limited engine torques due to the

amplitude of their seal movements, a movement the Quasiturbine brings back

to imperceptible. They have also the major geometrical defect of not

allowing a high geometric compression ratio, which makes them doubly inapt

for combustion engines. The compressible fluid must initially charge in pure

lost the residual chamber volume at Top Dead Center before providing the push, which

destroys their efficiency. An efficient positive expansion machine must be

capable of very high geometrical compression ratio, reducing the charging

loss to nearly zero, and this is one of the multiple Quasiturbine

objectives. Furthermore, the Quasiturbine has 2 different compress fluid

circuits (vane motor have only one), which double the torque, as well as

the specific power density.

Origin of the Quasiturbine Idea

The Quasiturbine researcher team has initially established a

list of 30 conceptual piston deficiencies

quasiturbine.promci.qc.ca/ETheoryQTVersusPiston.htm and as many Wankel

deficiencies

quasiturbine.promci.qc.ca/ETheoryQTVersusWankel.htm. The

Quasiturbine general concept

quasiturbine.promci.qc.ca/QTImages/QTBrevet12Fig1Net.jpg is

the result of an effort to improve both engines by suppressing the limiting

sinusoidal crankshaft and offering up to 7 degrees of freedom at design. The inventors have made a systematic analysis of engine

concepts, their value, their weaknesses, and their potential for improvement. All

improvement ideas converged when they suggested to make a turbo-shaft turbine having only

one turbine in one plane... In order to achieve that, the turbine blades had to

attached one to an other in a chain like configuration, where

the rotor acts as compressor for a quarter of a turn, and as engine the next

quarter of a turn... Furthermore, to be able to shape the pressure pulse at will

in order to optimized the thermodynamic and reach photo-detonation, extra

degrees of freedom at design needed to be introduced by a set of peripheral carriages. This

is the Quasiturbine, which is also a theory about efficient engine!

It is a type of rotary engine

invented by the Saint-Hilaire

family and first patented in the general configuration

quasiturbine.promci.qc.ca/QTImages/QTBrevet12Fig1Net.jpg in 1996. The engine uses a four-sided

articulated rotor supported by carriages that turns within a complex computer calculated oval

shape creating regions of increasing and decreasing volumes as the rotor

turns. The Quasiturbine design can also be used as an air motor, steam

engine, gas compressor or pump. It is capable of burning fuel using

photo-detonation, an optimal combustion mode of the future the piston cannot support...

Prior Art: « La

principale raison pour laquelle les concepts du 20 ième siècle ne se sont pas

développés résulte du fait qu'ils sont statiques et que les prototypes

correspondants ne tournent pas correctement, ni ne sont fonctionnels. Il aura fallu attendre la venue de

puissants ordinateurs personnels à la fins des années 1980, et les travaux de

simulation numérique de la famille Saint-Hilaire pour qu'émerge le concept

général dynamique de la Quasiturbine

www.quasiturbine.com , comprenant une vaste famille de nouvelles machines

quasiturbine.promci.qc.ca/QTImages/QTBrevet12Fig1Net.jpg incorporant

des solutions essentielles au bon fonctionnement et au succès ultérieur. Les

Quasiturbines incorporent aussi des profils de confinement « patinoires Saint-Hilaire

» plus généraux, qui permettent d'optimiser les usages. Les brevets

Quasiturbines citent une vingtaine de brevets principaux antérieurs,

malheureusement tous condamnés à l'échec anticipée par les simulations

numériques. Comme quoi l'informatique aura aussi aider à la révolution mécanique!

Il est consternant de constater qu'après tant d'années, la Quasiturbine reste

toujours incomprise... et demeure à tord souvent comparée à de nombreux concepts

très différents dans leur comportement, voir sans issu. »

When the distances

between the 2 wheels of a carriage is set to zero, the carriages become an

articulated jointure (no-carriage limit case). While there is no prior art for

the general Quasiturbine concept, a non exhaustive review of the no-carriage

limit case (SC model) is given in Quasiturbine patent back to 1902 (more patent

references exist in several countries, but the most significant are listed -

Numerical simulations have shown that all these implementations have conceptual

flaws or defects which make them non-practical running engine as patented). They

are applications not throughout studied and understood by their inventors at the

time and not comparable to the Quasiturbine in their behavior, abandoned for the

good reasons that they do not run properly (try them to see). No past reference

states or uncovers difficulties to which Quasiturbine already incorporates

solutions, and no one had found nor identified the superior properties of the

skating rink family type of confinement

profiles...

Since all referenced patents were expired (a couple

dozens of patents is almost like none

in the field of engines), a new and more advanced implementation

concept of the Quasiturbine SC model (without carriage) has been developed,

with a complex jointure carrying a complete seal set able to

meet the blades stress analysis. This implementation SC concept result of a detail

numerical simulations in order to define an optimized engine stator profile with

a center free rotor, and dynamically guide-free blades, including several

central differential solutions. Inventors which have been in the past working on

the no-carriage concept

variations have fail tenacity, and among them came this comment:

"Je ne vous en veut pas, mais je suis en rage

contre moi-même de ne pas avoir vu ni compris tout le potentiel de ce concept, d'avoir

manqué de persévérance, et ne pas avoir fait progresser cette invention pour amener

moi-même là où est la Quasiturbine aujourd'hui..." .

This is often the case when engine inventors do not start from basic

thermodynamic objectives, but rather focus their researches on a volume modulation machine,

leaving to hazard the later interest of the device. A path not followed by the

Saint-Hilaire family.

Some like to say that the Quasiturbine (the special simple case

without carriage) look like other rotaries, but none seem comfortable to say

that other rotaries look like the Quasiturbine! No matter the level of apparent

similitude, there are great differences between the Quasiturbine and other

rotary concepts, and those who fail to understand it theoretically, could sadly

discover it experimentally following considerable worthless effort and

investment.

To the exception of the Quasiturbine team, none of the inventors

having previously work on this no-carriage idea seem to have strongly believed

in it, at least not to the extend of actively promoting it during the last

decades. The Quasiturbine more advanced implementation SC concept and

general application disclosures create a new context in which some prior art

inventors tend today to re-interpret their works under a light not previously

available, crediting their past works with a plus value not known or apparent at

the time, and sometime source of un-confirmed historical pretensions which would

not have append without the recent Quasiturbine existence and growing

popularity... Not being the first inventor could be very frustrating, but should

never be humiliating.

Principle

In the basic single rotor Quasiturbine engine, an oval

housing surrounds a four-sided articulated rotor which turns and moves

within the housing. The sides of the rotor seal against the sides of the

housing, and the corners of the rotor seal against the inner periphery,

dividing it into four chambers. Contrary to the Wankel engine where the

crankshaft moves the rotary piston face inward and outward, the

Quasiturbine rotor face rocks back and forth in reference to the engine

radius, but stays at a constant distance from the engine center at all

time, producing only pure tangential rotational forces. Because the

Quasiturbine has no crankshaft, the internal volume variations do not

follow the usual sinusoidal engine movement, which provides very different

characteristics from the piston or the Wankel engine.

As the rotor turns, its motion and the shape of the housing cause each

side of the housing to get closer and farther from the rotor, compressing

and expanding the chambers similarly to the "strokes" in a reciprocating

engine. In the Quasiturbine engine, the four

strokes of a typical cycle de Beau de Rochas (Otto cycle) are arranged

sequentially around a near oval, unlike the reciprocating motion of a

piston engine. However, whereas a four stroke cycle engine produces one

combustion stroke per cylinder for every two revolutions, i.e. one half

power stroke per revolution per cylinder, the four chambers of the

Quasiturbine rotor generate four combustion "strokes" per rotor

revolution; this is eight times more than a four-stroke piston engine.

Quasiturbine Definition

The

Quasiturbine (Qurbine) is a no crankshaft rotary engine

having a 4 faces articulated rotor with a free and accessible center, rotating without vibration nor dead time, and producing a strong torque at low RPM under a variety of modes and fuels.

The Quasiturbine design can also be used as an air motor, steam engine, gas

compressor or pump. The Quasiturbine is also an optimization theory

for extremely compact and efficient engine concepts.

More to Understand...

While most rotary engines use the principle of volume

variation between a curve and a moving cord, this new engine concept makes use

of a "seven degrees of freedom X, Y, q, ø1,

ø2, ø3, ø4" rotor, trapped inside an internal housing contour, and does not

require a central shaft or support. This concept is the result of research for

an hybrid turbine-piston engine with a fixed center of gravity during rotation

(zero vibration). The invention is an assembly of four carriages supporting the

pivots of a four-element, variable-shape rotor. This rotor rolls on the inner

surface of a profiled stator shaped like a skating rink (just like a roller

bearing). During the rotation, the rotor components align alternatively in a

lozenge and a square configuration. This device can act as a pump, a compressor,

a flow meter, or as an engine (including pressurized fluid mechanical energy

converter). It is self-synchronized and uses no valve (only fixed ports in the

stator or alternatively, ports on the lateral side covers). Central support of

the rotor is not required for most applications. Four cycles are completed in

every rotation. The maximum geometrical compression ratio is a function of the

maximum diagonal ratio selected at design. As for turbine engines, ignition is

only required initially, since combustion is kept continuous between successive

cycles by way of an ignition transfer slot or cavity. The continuous combustion

produces an enhanced dynamic compression ratio. The device incorporates few

parts. It has an excellent torque continuity even at low rpm (Due to its high

torque pulsation rate, this device requires less flywheel effect and gearbox

ratio for most applications). It is suitable for uses such as aeronautics, where

high reliability is required. Having no oil pan, it can be operated in

completely submerged or hostile environments. The asymmetry of the strokes and

the precocity of the mixture intake and gas expansion (without excess volume

during expansion) allow for a better initial mechanical energy conversion. A

fast reduction in the combustion chamber of the temperature, the pressure and

the confinement time leads to less NOx production, and less heat

transfer toward the engine block, all contributing to improve the power density

and the efficiency over the piston engine. The Quasiturbine meets the hydrogen

engine criteria.

A Family of Devices

Because the Quasiturbine is defined by a set of 7 geometric

parameters (see the patents) which can be individually set to be positive,

negative or null, an infinity of Quasiturbine configurations can be achieved.

One of the most simple Quasiturbine geometry has no carriage (Model QT-SC) as

follows:

This illustrates some details of a Quasiturbine without

carriage (Model QT-SC).

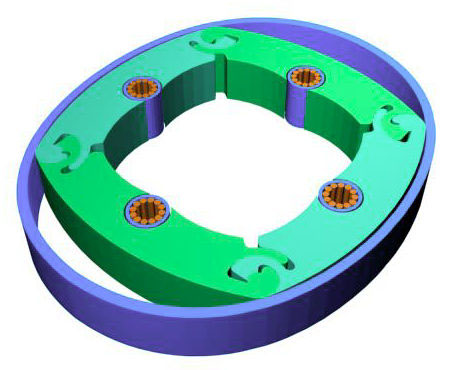

Other more complex geometries involve carriages (Model QT-AC) as

shown below.

QT-AC (With carriages) is intended for detonation mode,

where high surface-to-volume ratio

is a factor attenuating the violence of detonation.

Furthermore, the eccentricity is also an important geometric factor

which dictates the shape of the stator as a more or less complex oval, to a very

distorted shape still acceptable... The plurality of Quasiturbine designs produces different

pressure and torque characteristics, often very different from the piston and

the Wankel engine, which allows for operation mode not possible with the piston.

Each Quasiturbine device is at the crossroad of the 3 modern engines: Inspired by the turbine, it perfects the piston, and improves on the Wankel.

Improved Characteristics

The

Quasiturbine theory optimizes the use of time by eliminating dead times,

reallocating time among the different engine strokes and replacing the progressive torque impulses with impulse plateaus. This

theory concurrently takes advantage of space by adopting multi-functional and

homo-kinetic engine components which are indispensable at all times during

rotation, and demands continuous flow at the engine's intake and exhaust. This

theory optimizes 14 engine parameters at once and suggests pressure

profiles allowing the detonation.

The Quasiturbine

is a continuous flow engine at intake and exhaust. An engine's piston completes 4 strokes in two rotations, the Quasiturbine completes 32 ! Compressor, pump or turbo-pump

made possible

without any check valve or obstruction.

Continuous combustion, high torque, low

RPM, zero vibration, potentially oil free, fast acceleration, 20 times less noise, less pollution, and high power density (by

a factor of 4) in volume and weight.

Compatible with hydrogen and some Quasiturbine design accepting detonation mode.

Quasiturbine SC - Without Carriage

The SC model has not internal parts - because the center is accessible, all

engine components have a face accessible externally, including through the

center. This property is quite precious in application related to thermal heat

exchanges with the engine block.

When the eccentricity (here 0,578 for the model QT-SC, without carriage) is

chosen such as to produce a straight side on the top and on the bottom, the Saint-Hilaire

skating rink confinement profile is quite obvious:

Quasiturbine rotor confinement "Saint-Hilaire skating

rink profile"

This configuration displaces its entire volume every

revolution,

WHAT ABOUT A 3 LITERS DISPLACEMENT ENGINE

INTO A 3 LITERS ENGINE VOLUME!

Eccentricity can be still higher, but for current devices,

a less eccentric

Quasiturbine

is easier to built,

and well able to exceed piston engine performance.

Why does it Turn ?

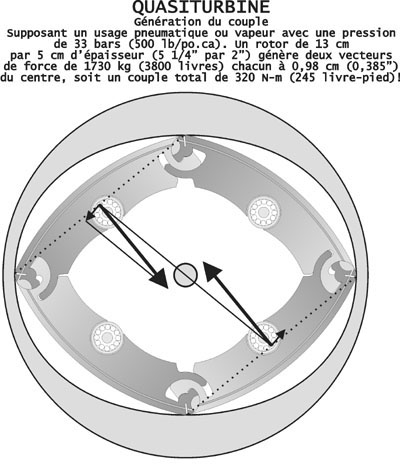

This diagram show the force vector in a Quasiturbine when one or

two opposed chambers are pressurized either by fuel combustion, or by external

pressure fluids. Because the pressure vectors are off center, the Quasiturbine

rotor experiences a net rotational force. It is that simple !

Click here for a 2000 pixels high

resolution image

This diagram compares piston engine with steam and fuel

combustion Quasiturbine.

Quasiturbine AC - With Carriages

More complex Quasiturbine designs can follow from the

defining set of equations. Contrary to the piston or the Quasiturbine QT-SC

(without carriage), which have volume characteristics near sinusoidal, the

more complex Quasiturbine designs can shape the volume pulse almost at will

by varying the parameter sets.

QT-AC (With carriages) is intended for detonation mode,

where high surface-to-volume ratio

is a factor attenuating the violence of detonation.

The parameters for the design below allow to shape the

volume pressure pulse to have a tip 15 to 30 times shorter than the piston,

which provide enhanced torque characteristics for pneumatic and steam

Quasiturbine. But more important, this design is most suitable for detonation

combustion engine mode, a superior mode the piston has failed to support for

over 40 years !

Furthermore, in detonation mode, the high

surface-to-volume ratio of this design

is an attenuation factor of the

violence of the detonation.

Pneumatic - Steam

All of the Quasiturbine family designs can be used in pneumatic and steam

mode.

Quasiturbine Uniflow Characteristic

In most reciprocating piston engines, the steam reverses its

direction of flow at each stroke (counter-flow). By entering and exhausting the

cylinder by the same port, the cylinder valve and walls are cooled by the

passing exhaust steam, while the hotter incoming admission steam is wasting some

of its energy in restoring the temperature. Some energy is further lost in

reversing the motion momentum of the mass of steam within the piston. The aim of the piston uniflow is to

remedy this defect by providing an exhaust port at the end of the stroke, making

the steam flowing only in one direction, but has the inconvenience of

recompressing some residual cylinder steam. Quasiturbine is a uniflow engine,

with the further advantage of not recompressing any residual steam, resulting in

superior energy efficiency. Recompressing residual steam means some

reversibility losses, and the pressure increases makes a substantial restriction

to the initial steam flow into the chamber, not to ignore the truncated cycle

near bottom dead center - None of this with the Quasiturbine.

Stirling

The Quasiturbine model SC is particularly

suitable for the Stirling mode (A pure thermal engine without intake and

exhaust).

Detonation Engine

Chemists know that the best way to burn fuel is with intense

laser radiation. The photo-detonation (Auto Ignition) occurs at slightly higher pressure than the

thermal ignition designated in the US as "Homogeneous-Charge

Compression-Ignition" HCCI combustion, in Europe as "Controlled Auto Ignition" CAI

combustion, and in Japan as "Active Thermo-Atmosphere" ATA combustion...

The efficiency at low load factor of the detonation engine is

more than twice that of the conventional Beau de Rocha (Otto) cycle, and considering that the load factor of a car is in average about 10 to 15%, this is not a small difference... Even if the subject

passionates the researchers, the thermic and photonic

ignition control in the piston is still an unsolved problem, and possibly a

dead-end ... that the Quasiturbine does overcome!

In combustion mode, the

Quasiturbine

QT-AC (With carriages)

is suitable for detonation mode,

where high surface-to-volume ratio is a factor attenuating the violence of detonation.

A White Paper

Quantum Parallel: The

Saint-Hilaire "Quasiturbine"

As The Basis For A Simultaneous Paradigm Shift in Vehicle Propulsion

Systems

Amidst

myriad, and many times unsupportable, claims of technological

breakthroughs capable -- fuel cells being at the top of this contention

-- of inducing vehicular design and engineering paradigm shifts, we have

concluded that the Saint-Hilaire "Quasiturbine" may very well provide

impetus to retire the piston engine. It has served humanity for nearly

two centuries, and has earned its rest. eMOTION!

REPORTS.com is providing a

comprehensive white paper that will perhaps allow you to reach the same

conclusion... Amidst

myriad, and many times unsupportable, claims of technological

breakthroughs capable -- fuel cells being at the top of this contention

-- of inducing vehicular design and engineering paradigm shifts, we have

concluded that the Saint-Hilaire "Quasiturbine" may very well provide

impetus to retire the piston engine. It has served humanity for nearly

two centuries, and has earned its rest. eMOTION!

REPORTS.com is providing a

comprehensive white paper that will perhaps allow you to reach the same

conclusion...

Historical Photos - Quasiturbine AC

Quasiturbine QT50AC - Basic drawings and photos of

prototype.

Quasiturbine QT50AC : Calculated torque, power

and consumption.

More Technical

Why is Quasiturbine

exceptional?

Encyclopedic summary

Quasiturbine differences with the Wankel

Quasiturbine differences with the piston engine

|