|

Since this website is widely

dedicated to education,

and because early projects are precious part of the innovation history,

the QT50AC first project is more than a curiosity...

Q50AC Basic Drawings

Understanding...

While most rotary engines use the principle of volume

variation between a curve and a moving cord, this new engine concept makes use

of a "seven degrees of freedom X, Y, q, ø1,

ø2, ø3, ø4" rotor, trapped inside an internal housing contour, and does not

require a central shaft or support. This concept is the result of research for

an hybrid turbine-piston engine with a fixed center of gravity during rotation

(zero vibration). The invention is an assembly of four carriages supporting the

pivots of a four-element, variable-shape rotor. This rotor rolls on the inner

surface of a profiled stator shaped like a skating rink (just like a roller

bearing). During the rotation, the rotor components align alternatively in a

lozenge and a square configuration. This device can act as a pump, a compressor,

a flow meter, or as an engine (including pressurized fluid mechanical energy

converter). It is self-synchronized and uses no valves (only fixed ports in the

stator or alternatively, ports on the lateral side covers). Central support of

the rotor is not required for most applications. Four cycles are completed in

every rotation. The maximum geometrical compression ratio is a function of the

maximum diagonal ratio selected at design. As for turbine engines, ignition is

only required initially, since combustion is kept continuous between successive

cycles by way of an ignition transfer slot or cavity. The continuous combustion

produces an enhanced dynamic compression ratio. The device incorporates few

parts. It has an excellent torque continuity even at low rpm (Due to its high

torque pulsation rate, this device requires less flywheel effect and gearbox

ratio for most applications). It is suitable for uses such as aeronautics, where

high reliability is required. Having no oil pan, it can be operated in

completely submerged or hostile environments. The asymmetry of the strokes and

the precocity of the mixture intake and gas expansion (without excess volume

during expansion) allow for a better initial mechanical energy conversion. A

fast reduction in the combustion chamber of the temperature, the pressure and

the confinement time leads to less NOx production, and less heat

transfer toward the engine block, all contributing to improve the power density

and the efficiency over the piston engine. The Quasiturbine meets the hydrogen

engine criteria.

Drawings and photos

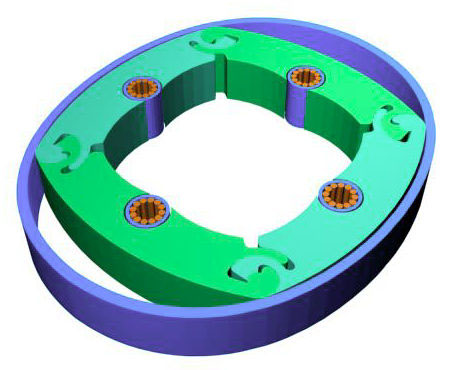

Quasiturbine Engine - Stator profile, with groove

and quasi circular

pressure ring positioning.

QT50 Data

BASIC DATA EXAMPLE:

Major axis = 5.570". Minor axis = 4.700"

Each chamber volume = 1.49 po2 x

thickness (po)

Displacement volume per rotation = 4 x 1.49 x

thickness (po) , po3/rotation; or 4 x 9.6 x thickness (cm) , cm3/rotation

Assuming a thickness of 2.000"

Aspirated volume per rotation = 11.9 po3

/rotation; or 200 cm3 /rotation

(The power generated must be compared to a 2 stroke

engine)

"Saint-Hilaire" contour

Comment on the

"Saint-Hilaire" contour profile calculation

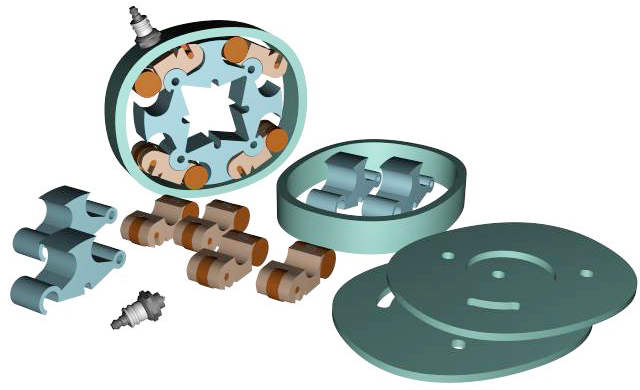

Quasiturbine Engine - Components template

(Lozenge,

carriage & mechanical coupling)

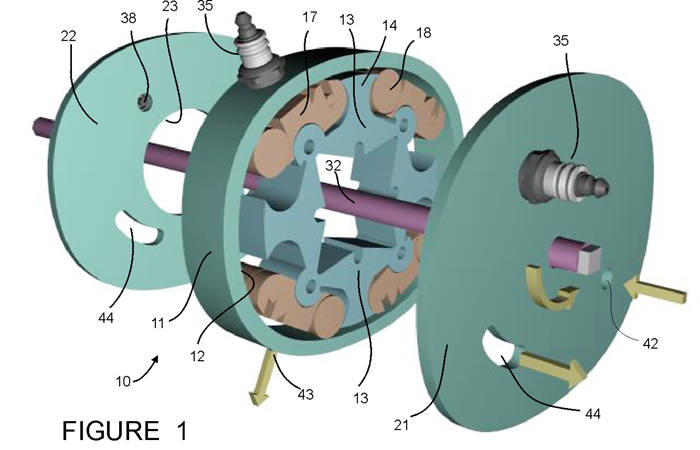

Blow up diagram of the

prototype

Click on the illustration for a higher resolution

Quasiturbine Engine: Blow up of stator, rotor assembly,

carriages, port positioning and mechanical coupling.

(Square arrangement on the left, lozenge on the right)

10 - L'ensemble moteur

11 - Boitier incluant 2 parois

12 - Contour SAINT-HILAIRE

13 - Pale pivotante

14 - Bourure

15 - Prise de traction

16 - Pivots

17 - Chariot

18 - Rouleau

19 - Centres de rouleau

20 - Trajectoire centre de Pivots

21 - Paroi avant

22 - Paroi arrière

23 - Ouverture dans paroi arrière

24 - Joint tiroir

25 - Join papillon

26 - Joint divisé avancé

27 - Ressort plat |

28 - Joint linéaire

29 - Joint arc

30 - Joint circulaire

31 - Joint chariot

32 - Arbre

33 - Bras de couplage

34 - Tringles de poussée

35 - Bougie

36 - Canal d'allumage

37 - Fenêtre de bougie

38 - Fenêtre de bougie paroi

39 - Fenêtre

40 - Bouchon

41 - Fénêtre carburateur

42 - Fenêtre carburateur paroi

43 - Fenêtre échappement

44 - Fenêtre échappement paroi |

More Photos

(click on the photo to enlarge full page or view more photos)

Plexiglas prototype: Rotor assembled, with the

stator and lateral covers. Plexiglas prototype: Rotor assembled, with the

stator and lateral covers.

Plexiglas prototype all assembled in the stator,

with the lateral covers. Plexiglas prototype all assembled in the stator,

with the lateral covers.

Perforation template applied to Plexiglas

prototype. Perforation template applied to Plexiglas

prototype.

Drawing template for stator profile, with lateral

covers. Drawing template for stator profile, with lateral

covers.

Some anterior prototypes ! Some anterior prototypes !

The first metal prototype built in February 1997 The first metal prototype built in February 1997

More Technical...

QT50AC

Characteristics

|