quasiturbine.promci.qc.ca

Page replaced by: EProductQT75SCAcademic.htm

* * * * *

QUASITURBINE EDUCATIONAL

QT75SC

FRANÇAIS -

ENGLISH

Occasionally available on www.ebay.com - Search

for "Quasiturbine"

Price : 1890,00 $US in America or 1890,00 Euro

elsewhere (equivalent of 40 students at

50

$-euro each! )

M

Attach an accepted copy of the present pages with your purchase order.

(For completely assembled engine, see

http://quasiturbine.promci.qc.ca/QTdesireacheter.html)

LET THEM INVOLVE IN THE

"QUASITURBINE STUDENT INTERNATIONAL CHALLENGE"

IT IS FUN AND HIGHLY EDUCATIONAL !

SET OF BASIC PARTS (PARTIAL KIT)

FOR CONSTRUCTION

OF A

DEMONSTRATION PROTOTYPE OF A

QUASITURBINE PNEUMATIC ENGINE

(Air motor)

Quasiturbine Académique Inc. offers a set of educational basic parts (partial

kit),

from parts

similar (but not as powerful) as those used in commercial Quasiturbine QT75SC-Pneumatic models.

|

It is the buyer and/or operator

responsibility |

The Quasiturbine technology is under development

and the prototypes are still experimental.

These prototypes only have an academic-educational vocation,

and consequently do not seek to meet high standard of performance or durability.

Although functional, these sets of basic parts are not intended for commercial practices.

They are not intended to produce useful power, nor for

steam or hydraulic use.

Once supplemented and assembled, these pneumatic-academic prototypes of

demonstration turn under the effect

of compressed air or nitrogen at a pressure as low as 0,3

bar (5 psi)

and must

not exceed 1500 RPM and/or 2 bars (30 psi) at the pressure gauge

(About 1 HP flow-in).

However, don't anticipate a perpetual loop motor-compressor-motor,

nor to extract 1 HP out of a 1 HP compressor, this motor will not do this

kind of magic !

To make a success of this project, it is essential to have good knowledge in

mechanics.

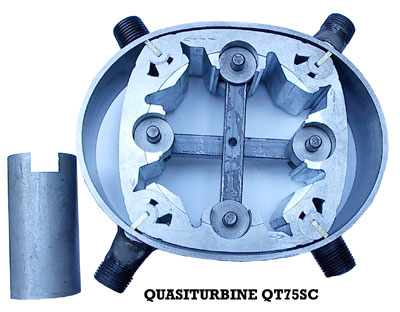

External engine size is about 19.8 cm (7 7/8 inches) in diameter

by about 6.4 cm (2 1/2 inches) thickness.

Well constructed and assembled, well lubricated and operated within the limits,

these prototypes can generally totalized several hundreds of hours

without significant breakdown and/or weariness.

BY THE PROJECT (not necessarily provided)

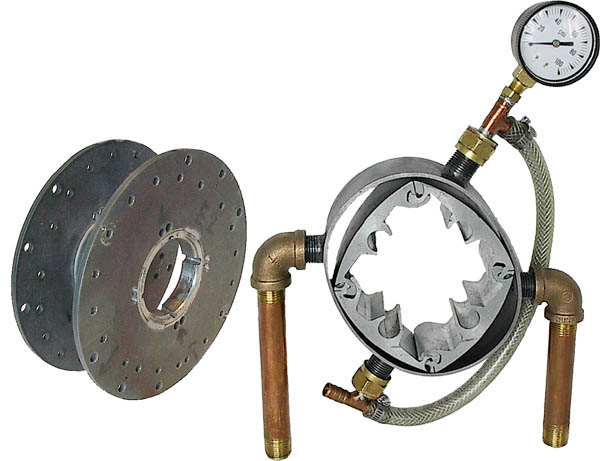

(The QT75SC is similar to the QT50SC shown in this picture)

Includes a simplified differential and

a central shaft.

For educational purpose, it is suggested to observe the rotor turning by the

openings on the axis of the side covers.

These prototypes do not

use lateral seals,

sealing being only assured by tight side tolerance with the assembly and by

the lubricant used.

* * *

WHAT IS INCLUDED

IN THE SET OF PARTS OFFERED (partial kit)

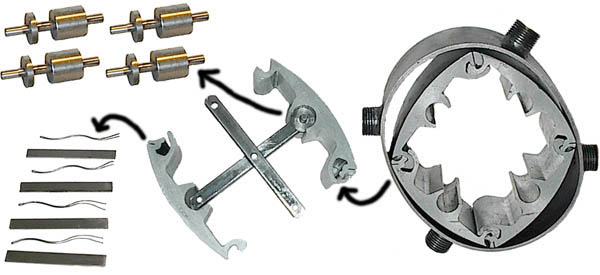

(The QT75SC is similar to the QT50SC shown in this picture)

1) A set of 4 pivoting blades slightly oversize in thickness.

2) A steel stator slightly oversize in thickness, whose interior surface is

already rectified and polished,

and including 4 radial windows (two intakes and two exits,

standard NPT 1/2").

3) A set of 4 slightly oversize contour seals and their associated springs

(seals which have to be slightly rectified to accommodate the contour).

4) 4 cylindrical supports and 4 axes for the pivoting blades.

5) Two central cross arms (no suitable as power takeoff).

6) A suggested drawing to help making the lateral side covers.

7) Includes a simplified differential and a central

shaft.

7) A Guide of indicative instructions for assembly and construction.

* * *

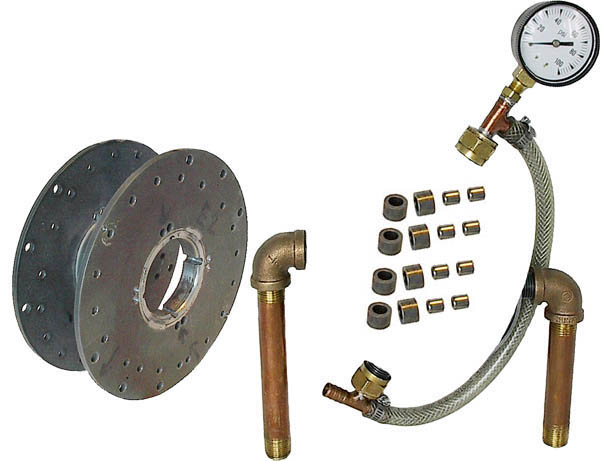

IN THE SET OF PARTS OFFERED

(The QT75SC is similar to the QT50SC shown in this picture)

1) Two lateral circular side

covers including the

tracks for the rollers supporting the pivoting blades.

2) 8 central rollers supporting the pivoting blades and their needle bearings.

3) The connecting holding bolts.

4) Ports of admission and exhaust compatible with NPT 1/2" standard .

5) Final correction, settings with the dimension, selection of the tolerances,

polishing, adjustments, assembly...

6) The foot for anchoring the engine to a table (essential to build it).

7) The tools, abrasive pastes and the facultative antifriction pastes.

8) The pin-hole pressure gauge, the tachometer and compressed air

or nitrogen (neither

the compressor, the bottle, nor the regulator).

9) The static or dynamic

rotor balancing has not been verified.

10 -

Includes a simplified differential and a central

shaft.

* * *

- Familiarize yourself well beforehand with the Quasiturbine

technology (see the associated site

- Always make it turns gradually (without abrupt acceleration).

- In phase of running in, reposition the rotor before each starting

by making turn the rotor by the central shaft.

- Always ensure that the rotor is adequately lubricated (pneumatic tool oil).

- Ensure that the hoses and fasteners (particularly the flexible) are of

quality and well anchored.

- Use a good pressure regulator to limit the maximum pressure and place a

pressure gauge close to the engine intake.

- It is recommended not to exceed 1500 RPM and/or 2 bars (30 psi) at the pressure gauge

(About 3 HP flow-in).

- The use of a tachometer (with magnetic pick up, like the one used on bicycle

?) is also recommended.

- Once in use, the engine will progressively break-in and rotate better and

better,

the fact to later dismantle periodically the engine may require a new

running-in period every time...

- Never exceed the recommended limits.

REMARK ON PNEUMATIC SYSTEM EFFICIENCY

An high efficiency pneumatic motor does not guaranty the high

efficiency of the entire pneumatic system.

All gas heat up during compression and cool down during relaxation.

The cooling effect must not be under-estimate. As an example, a typical 200 bar

(atm.) cylinder

empty adiabatically (without thermalization to ambient temperature) gives at the

end an air so cold

that its volume is then a 1/4 of that of the air once back to the ambient

temperature (isothermal relaxation).

In those temperature conditions at the entrance of a pneumatic motor, the

efficiency is catastrophically low

and the lubricant solidified, increasing considerably the internal engine

friction...

Generally, the reversibility of the compression - relaxation cycle reduces with

an increase in pressure,

which favours for high efficiency consideration the use of the lowest design

pressure possible.

The measurement of the exhaust temperature gives generally a good indication of

the efficiency,

since the minimum of energy lost into the environment correspond to

an exhaust temperature equal (neither inferior, nor superior) to the ambient

temperature.

This condition can be achieve by a slight heating (solar) of the gas before its

entry into the pneumatic motor.

Since the Quasiturbine rotates from pressure as low as 1/10 of atmosphere (bar)

(one psi !),

one understand why the Quasiturbine is so well adapted to high efficiency

system...

- These prototypes must be supplemented, assembled and

operated under the constant supervision of qualified adults.

- Anchor the prototypes well on a table before each start-up.

- Never exceed the limits and suggested conditions of operation.

- Wearing safety glasses, mask and fastener hair is recommended.

- The demonstration room must be well ventilated.

- Check the tightening of the bolts and adapters. Be wary of the rupture

or the decoupling of any of the flexible hoses.

- Have a distant valve allowing to cut the air flow (nitrogen) as

needed.

- Particularly during grinding under compressed air, it can happen that the

rotor be at a dead point,

and refuses to turn when the pressure is applied.

This situation is unstable and call for urgent pressure release.

Then and in absence of pressure, slightly turn the rotor with the central

shaft and pressurize

it again...

- During the demonstration, nothing should approach the central zone of the rotor

and makes the observations at a distance of 50 cm (20 po.) or more.

-

Always remain vigilant!

- Includes a simplified differential and a central

shaft.

SALE DETAILS

GENERALITIES

- Sale and operation is restricted to adults only.

- Sale priority goes to schools, colleges and universities.

- Use for academic demonstration only (commercial modification is

not suitable, nor recommanded).

- Pneumatic air-nitrogen prototype only (less than 2 bar - 30 psi),

no steam conversion attempt must be made (could be very dangerous).

- Prototypes intended for demonstration of short durations.

- Additional parts of replacement can generally be ordered by those having acquired the kit.

- The Brief Instructions

Guide suggests data and methods only as

indication,

and it is up to the purchaser to make sure that he-she understands well

the steps and the details of his project.

- To make a success of this project, it is essential to have good knowledge in

mechanics,

in machining technique and assembly.

CONDITIONS

- The Purchasers release Quasiturbine Académique Inc. of all responsibilities

relative with the use.

- Sold without specification, nor guaranteed of performance or durability

(variable according to the quality of the assembly).

- Guaranteed of the seller (Quasiturbine Académique Inc.) is limited to the

replacement of the parts with manufacture defect.

- The prototype can not be used to make research on the Quasiturbine

technology,

neither to make reverse engineering, or to make copies.

- The purchasers must have read the present page as part of the purchase order

and invoice,

and

declare themselves satisfied with it.

- Sales are assumed done in Montréal, Québec Canada.

- The present document and conditions will be transferred

to the chain of future owners of this prototype.

- If there is intellectual propriety risk, the seller can simply refund and not

deliver.

PRICE AND SHIPPING

- The set of basic parts (partial kit) is

sold on

at a starting price depending of the monetary zone of 1890,00 $US or 1890,00 Euro (equivalent of 40 students at

50

$-euro each! )

-

Attach an accepted copy of the present pages with your purchase order.

- The price includes the applicable local sale taxes if required, but not the shipping costs.

- Approximate Weight of the parcel is 5 kg (12 lb).

- The insurances (mandatory) and customs fees are the responsibility for

the purchaser.

- As possible, shipping will be made in the 3 weeks following the

reception of the payment,

or according to the production capability of the moment (to be notified when ordering).

* * * * *

SET OF BASIC PARTS (PARTIAL KIT)

FOR CONSTRUCTION

OF A DEMONSTRATION PROTOTYPE OF A

PNEUMATIC QUASITURBINE ENGINE QT75SC

|

It is the buyer and/or operator

responsibility |

Notice - This document is written

to be used by a mechanic experienced with the said techniques.

If you do not understand well some sections, you are invited to consult a

professional mechanics.

Follow attentively the instructions and read again at each later dismantlement and re-assembly.

I - Attention: The rotor is a deformable assembly articulated

in square and lozenge.

OF THE ROTOR PASS ITS LIMIT

nor strikes the pivoting blades to articulate the rotor

(what could distort the pivots and the grooves of

the contours seal).

II - Attention: Abrasive

grinding paste, only if necessary to use,

ALWAYS USE IT IN "VERY SMALL QUANTITY"

(hardly visible quantity) abundantly diluted in a lubricant.

Avoid the formation of a film of paste on surface to be polished.

NEVER ADD GRINDING PASTE TO THE ASSEMBLED ENGINE

Once finished, always clean well with solvent all the parts and the tools

contaminated with the paste.

III - Attention: If the rotor does not turn freely

by

hand,

DISMOUNT IMMEDIATELY

otherwise irrevocable grooves can occur on the interior face of the stator or

elsewhere.

IV - Attention: Foreign bodies

OF FOREIGN BODIES IN THE QUASITURBINE

A way is to use screen and make sure the intake

line goes from bottom up.

V - Attention: These prototypes must be supplemented,

assembled and be operated under the constant supervision of qualified adults.

OTHER SAFETY MEASURES

- These prototypes must be supplemented, assembled and

operated under the constant supervision of qualified adults.

- Anchor the prototypes well on a table before each start-up.

- Never exceed the specifications and suggested conditions of operation.

- Wearing safety glasses, mask and fastener hair is recommended.

- The demonstration room must be well ventilated.

- Check the tightening of the bolts and adapters. Be wary of the rupture

or the decoupling of any of the flexible hoses.

- Have a distant valve allowing to cut the air flow (nitrogen) as

needed.

- Particularly during grinding under compressed air, it can happen that the

rotor be at a dead point,

and refuses to turn when the pressure is applied.

This situation is unstable and call for urgent pressure release.

Then and in absence of pressure, slightly turn the rotor by the shaft and pressurize

it again...

- During the demonstration, nothing should approach the central zone of the rotor

and makes the observations at a distance of 50 cm (20 po.) or more.

-

Always remain vigilant!

- Includes a simplified differential and a central shaft.

Parts provided

VI - The the rotor and the stator

thickness fit.

These parts are delivered slightly over-dimensioned.

Do not use electric tools or motorized grinding stones.

It is recommended to make this dimension setting by hand

with the

already encased pivoting blades ones in the others (Always match the

pivot numbers - Facing the one or two dots)

by using sandpaper posed on a plane surface, the rotor being then caped also

by a plane

object.

The rotor must have good parallelism in its two extreme lozenge positions. It is

then recommended to deform it while lapping.

Control the rotor thickness for different geometries by squeezing it in-between

two flat surfaces.

Attention not to déburer (to round the edge)

at the stator interior, which

would increases the leaks.

For the compressed air, it is suggested a minimal difference in

thickness of 0,002"(maximum 0,005")

between the rotor and the stator, and check free rotation once assembled

(the numbered surface of the rotor should be on the same side as the arrow

grooved in the stator),

like while moving under pneumatic in order to taking into account a possible heating

dilation of the pivots.

Multiple tests will guide you towards the optimum value.

Multiple resumptions of the dimension settings of the stator

and rotor are generally possible.

QT75SC Pneumatic (the simplified differential and its shaft actually replace the

central cross).

(Rotor average diam. 6 in. by 2 in. thickness)

VII - The interior surface of the stator.

This surface was already brought to the dimension and reasonably polished.

It is necessary to avoid deteriorating this critical surface, because it would

be so to speak be non reparable. ..

This surface required a complex polishing equipment - Do not attempt to re-grind

this surface.

VIII - The fitting of

the grooves and the contour

seal .

Each pivoting blade comprises a contour

seal

which must move freely in his

groove. It is suggested not to sandpaper

or grind the

interior of this grooves,

but rather to notch it using a blade of wished width,

typically 3,18 mm (0,125") with square and sharp

ends.

The back and forth of the end of this blade should be enough to form the

grooves.

The set of parts includes slightly

oversize seals,

the length must be brought back to about 0,003"

shorter than the thickness of the stator.

Once at the right dimension, the contour seal inox sleeve (when present)

must be slightly squeezed

with its contour seal inside to insure the best movement with minimum of

friction.

The edge of the seal in contact with the stator

contour must be round on a stone to avoid gripping,

and the opposite edge must be grinded down in order to leave a reasonable play

in the rotor.

Undulated springs to place behind the contours

seals are provided

but the tips must be smooth out not to grip into the seal, neither scratch the

lateral covers.

(Notice that rotation in excess of 1500 RPM may provoke early fracture of the

springs).

Always check the unrestricted passage of these

seals during the

rotation of the rotor.

IX - Supporting blade rollers axis and the

simplified differential. These parts are provided

and already assembled in the pivoting blades and the rotor

at delivery. If need,

it is possible to dismount them and put them back up again.

They do not require any intervention other than checking the length to

ensure a sufficient gap in the between lateral side covers.

Lubricate well all the parts, and periodically the flat part on the shaft.

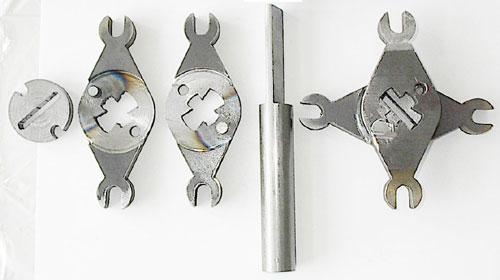

Simplified differential : The components on the left, the shaft at the center,

and a view once the left parts are assembled on the right.

Parts not provided

X - Central

supporting rollers and bearings of the

pivoting blades. These parts are not provided,

because they must be made according to

the residual tolerances measured

between the rollers on the rotor

and the supporting track in the lateral side covers. It is strongly suggested

to mount these rollers on bearing (e.g. Torington B56),

and their external diameter will be close to 0,780"

in order to allow a free movement of the

lateral side cover tracks in and out of

the rotor.

Polish the sides of the rollers on bearing and make an initial generous

lubrication

to avoid wear against lateral sides covers and the rollers supporting shaft

support .

Important : It is not acceptable

to force the side cover tracks into the rotor

and if that is the case, it is necessary to under-size the

external diameter

of the rollers supporting the pivoting blades.

If needed, the central 1/2" diam. hole of the blade supporting wheel-bearing

must be slightly enlarge to make sure the bearing casing (type Torington #B56)

moves freely axially in this hole.

Attention : Do not attempt to rotate the rotor without the 8 wheel-bearing

well in place on the supporting tracks.

These wheel-bearing are as important as the bearings in the pistons engine,

and an attempt to rotate without them shorten the engine live time to a few

minutes !

XI - The lateral side covers.

These lateral side covers are not

provided because they can take several external forms

(square, rectangular, circular. ..) to suit the local needs. They do not present however an particular

difficulty of realization.

Although the commercial versions require a quality steel, the

demonstration versions are well

served with ordinary steel.

Aluminium is not suitable unless a flat steel sleeve is added and an steal ring

insert is used for rollers tracks.

The lateral side covers can be cut in the mass in

only one part, or be made of two

pieces welded together.

The following suggestive drawing present a possible distribution of the positioning of

the bolts. Notice the protuberant track.

It is important to

precisely position the holes of the bolts, because

their location are also used for centring the stator.

The central circle on the lateral side cover drawing is the maximum diam.

suggested for that opening.

A smaller diameter hole would improve the cover rigidity

(as for example a 1" diam. only to accept a needle bearing type Torington

#B128).

One of the lateral covers may have 10-24 threaded stator holes to conveniently

avoid using nuts !

XII - Connecting holding bolts. These bolts are not

provided.

It is suggested to use 3/16" (10-24)

bolts of sufficient length, and

quality nuts.

The cheap steel bolts elongate with time and are not adequate. Use only forged

steel bolts grade 9 or higher (Allen head).

Suggested phases of assembly

XIII - The centring of the stator. This centring

is important, and it is made in reference to the connecting holding bolts.

Before closing the cover, it is recommended to extend the rotor fully in the

diamond configuration,

and to make sure all four contour seals are equally extended.

Angularly, make sure that the stator is in the

wanted position in relation to the

lateral side covers orientation.

Ensure that the bolts are

straight, or substitute some by rigid

rods at the

lateral side covers assembly time.

Use external appropriate spacers at top and bottom,

and on the left and the right, in order to hold the stator correctly.

Tighten the bolts well, because they must immobilize the stator in place.

The standard academic stator has no privileged direction of rotation, which is

not the case for the

rotor direction of rotation : In between two successive contour seals,

localized the jointure interstice,

which should be head of the rotation when the rotor rotates.

Note : Due to the in-out port symmetry of the academic stator,

the air motor can be assemble without at that stage considering the rotor

direction of rotation,

which direction being later defined by examining the jointure interstice

through one of the ports,

which ports will then be assign as in or out according to the rotor

preferential direction of rotation.

In this case however, the engine base support may not be on the desired side

for a given direction of rotation.

XIV - Assemble and test one step at the time.

Place the rotor without its seals and neither its rollers in the engine casing

and tide all the bolts

(important to avoid the deformation of the lateral side covers). Ensure that the rotor move freely.

Put it apart, add the contour seals and bolt it again to check the free rotor

movement in between the two lateral side covers.

Keep doing that way for each assembly step.

This way to do is crucial not to damage the components of the engine.

A resumption of the thickness of the rotor and stator are generally

possible,

but it should then be made sure that the 4 axes, 4 supports and 8 rollers of

central pivoting blades

do not exceed the total thickness of the

stator.

Check the lateral side covers with a ruler for deformation.

Excessive torque on the contour bolts or the insufficient lateral side covers

rigidity may lead to spherical cap deformations.

and make impossible the proximity leakproof rotor condition with the lateral

side covers.

If needed place 4 cylindrical spacers, diam. 1/4" and having the same length as

the stator thickness,

near the engine attachment holes on the external perimeter. Control again the

external planitude.

XV - Use of anti-grip past : This paste is

not essential, neither recommended,

but it can facilitate the start-up by decreasing the risk

of damaging the parts,

particularly on the pivoting blades, the

grooves and contour seals,

like on the interior surface of the stator when use for the

first time.

Others suggestions

XVI - A hand key tool to reposition the rotor by hand.

For checking the assembly

and before each start up by compressed air, it may be

useful turn the rotor by hand.

For that, it is recommended to used a hand key

tool fitting on the shaft.

Before concluding that the engine is difficult to turn, it is recommended to

move the hand key tool alternatively in both directions.

The central simplified differential has a slot

to insert the flat part of the shaft of 3/4" diam. (thickness 3/16").

For a better holding and self centering, a different shaft could have its flat

section extended

such as to enter also in the opposed side cover bearing, and even further

extend outside the engine where it could be lock-in.

The simplified differential efficiently smooth out the engine torque but is not

as robust as an industrial units.

Attention : Be carefull to always remove the hand key before

running the engine !

XVII - A foot for

engine support. The engine

can produce violent kickback,

and as it has a substantial weight, it is imperative to immobilize it well

before each use.

It is thus essential to build a solid and adequate holding support.

Take care of the engine attachment method in all circumstances :

Important : Always attach the engine by only one of the lateral side covers

(the one on the power takeoff side)

using short bolts in peripheral holes,

in order not to add undesirable pressure in between the 2 side covers, which

could deform the engine casing.

XVIII - Periodic lubrication. During the

first 2 braking-in running hours,

periodically add oil in the feeding air line to help exiting the braking-in

particles.

Later, use moderate oil quantity and no more than necessary to wet the chamber

walls.

Furthermore, since the rotor lateral leakproof is only assumed by

the lateral side covers proximity,

a generous periodic lubrication help to complete the leakproof.

This engine is not

particularly demanding on lubrication,

but the materials chosen for these prototypes require nevertheless a periodic

lubrication.

Every hour of operation, add

some pneumatic tool oil drops in the

intake manifold

(motor oil emulsions, oxides and crystallizes under adiabatic cooling, so it

is not recommended).

Do not allow excessive oil or liquid accumulation in the central engine

area

to avoid a blade fatigue

by hydraulic lock of the micro pivots cavities.

Periodically, dip the flat section of the shaft in oil (use air tools

oil only)

to lubricate the central power grip zone.

XIX - The operating temperature. Air

expansion produces a powerful cooling.

These prototypes

are intended for demonstrations of short durations

of 30 minutes or less. If the

prototype must go for uninterrupted longer periods,

monitor the temperature of the

lateral side covers and stop at once

if it

does increase even slightly.

This prototypes has no dilatation provision for use with steam - Do not try

hot.

XX - The static or dynamic

rotor balancing has not been verified

and is generally not required for demonstration.

Everyone is free to improve the balancing at will if desired.

Version subject to changes without notice - December 17, 2004

******************************

Instruction

for theTo :

Quasiturbine Tronçonneuses Inc.

Casier 2804 - 3535 Papineau

Montréal Québec H2K4J9

514-527-8484 Fax: 514-527-9530

Associated website : quasiturbine.promci.qc.caA partial Kit of academic prototype

of the Quasiturbine model QT75-SC Pneumatic

(With a simplified central differential and shaft,

but not intended for useful energy production,

not to be integrated to a or several commercial products).

Only for academic purposes

and without guaranty of performance.

To be use only under competent supervision.Sale assumed done in Montréal, Québec Canada

Price including local sale taxes if applicable (1890,00 US $)The web page quasiturbine.promci.qc.ca/QTAcademiquePneumatiqueJeu.htm

is an integral part of the present purchase order

and constitute the terms and conditions assumed accepted by the buyer,

including the respect of the laws and the discharge of responsibility.__________________________________

Authorized Officer

******************************

| Retour au menu principal Quasiturbine / Return to Quasiturbine main menu |

Quasiturbine

Tronçonneuses Inc.

Casier 2804, 3535 Ave Papineau, Montréal Québec H2K 4J9 CANADA (514) 527-8484 Fax (514)

527-9530

http://quasiturbine.promci.qc.ca

quasiturbine@promci.qc.ca