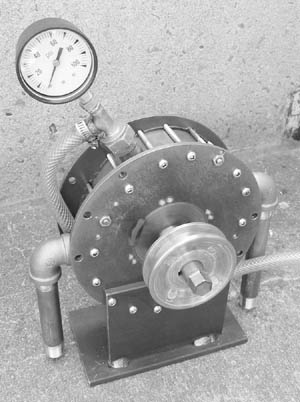

Quasiturbine Model QT75SC pneumatic-steam (similar to the QT50SC Without Carriage, here shown)

Usable with intake sustained pressure as low as 20 to 50 psi!

See the replacement page QT5LSC Pneumatic

QUASITURBINE ZERO

VIBRATION

Model QT75SC Pneumatic

(air motor) / Steam

now available as pre-commercial

prototypes

SEE

ALSO :

SET OF BASIC PARTS (PARTIAL KIT)

FOR ACADEMIC

DEMONSTRATION

PROTOTYPE

RESEARCH APPLICATION PROTOTYPES made by

QUASITURBINE TRONÇONNEUSES INC.

(A qualified manufacturer under a privileged QT-BLADES supply license agreement)

Casier 2804, 3535 Ave Papineau, Montréal Québec H2K 4J9 CANADA

(514) 527-8484 Fax (514) 527-9530

http://quasiturbine.promci.qc.ca

quasiturbine@promci.qc.ca

Those pre-commercial research application prototypes are specially well built.

UNIT

COMPLETE and RUNNING !

Pneumatic (air motor or air engine) - Product description :

The Quasiturbine research application prototype has been developed

from a chainsaw application. Casing and rotor weight

have not been optimized, and weight about 20 pounds (cylindrical outside

measurement are about 7 7/8" in diameter and

2 1/2" thick excluding peripherals). It

has a total 600 cc intake volume per revolution. The rotor and

the cylindrical external casing are built of high quality steel (no aluminium

prototype at this time). All basic prototypes comprise a cylindrical stator bloc, a rotor

and an 3/4-inch diameter shaft throughout. 2 intake ports 1/2"

male NPT pipe threads and 2 exhaust ports 1/2"

male NPT pipe threads. Preferred less than peak 100 psi. Periodic lubrication

required. Ideal for mining industries applications and for air vehicle (air

car).

Quasiturbine Model QT75SC pneumatic-steam (similar to the QT50SC Without Carriage,

here shown)

Usable with intake sustained pressure as low as 20 to 50 psi!

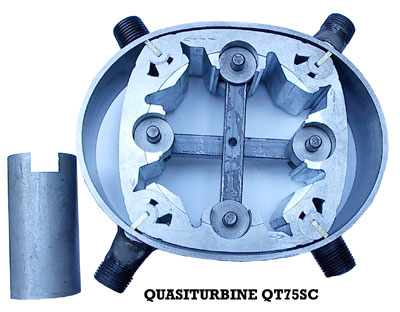

QT75SC Pneumatic shown without the differential and the central shaft.

Quasiturbine Model QT75-SC has a volume of 75 cc per chamber,

and the swept volume is 8 chambers per revolution (4 on the top, 4 on the

bottom), which totalized 600 cc per revolution.

At 1800 RPM, this is 1,1 cubic meter per minute at intake (what ever the

pressure) !

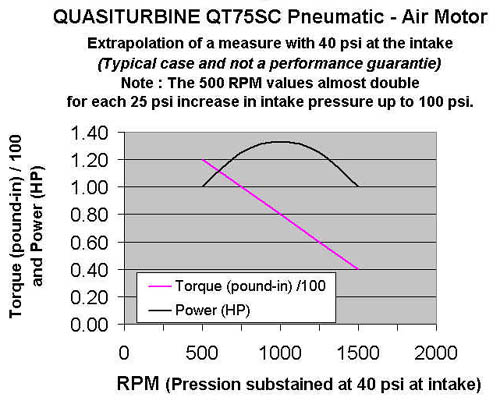

QT75SC -

Measured Pneumatic Characteristic - Air

(A typical value given as indication only. May vary from on QT to an other) :

In the present state of development, one needs to typically apply 10-15 lb/po2

(psi)

at the intake pressure gauge to obtain a free rotation of 500 RPM.

To produce 1 HP at 500 RPM (not the maximum power),

one needs to apply about 40 lb/po2 (psi) at the intake pressure

gauge.

The - effective differential internal pressure - is then about 25 lb/po2

(psi), producing a torque of 120 lb-po.

Model QT75SC Pneumatic (Rotor average diam. 6 in. by 2 in. thickness)

The values vary linearly around this low pressure

point

but must not be inconsiderably extrapolated to high pressures

(Around 1 HP by 25 lb/po2

(psi) still at 500 RPM).

(At 3 times this RPM the power would vary as 3 HP by 25 lb/po2

(psi) effective, which is

theoretically compatible with the non-verified objective to exceed 10 HP at 3000

RPM with only 100 (psi) at intake).

Le débit d’air (non mesuré) consommé par le moteur est alors de 75cc x 8

chambres par tour x 500 tours/min = 300 litres/min

à une pression entre la pression effective de 25 psi et la pression d’entrée de

40 psi.

Pour tirer le plus d’énergie possible de l’air comprimé, il est essentiel de

s’assurer

que la température de l’air à l’entrée de la Quasiturbine est voisine de la

température ambiante,

et même sensiblement plus élevée si possible.

|

Example 1 : RPM = 1000; Pressure = 40 psi ; Pfm = 20 psi

Example 2 : RPM = 3000; Pressure = 100 psi ; Pfm = 50 psi

Extrapolation not verified. |

REMARK ON PNEUMATIC SYSTEM EFFICIENCY

An high efficiency pneumatic motor does not guaranty the high

efficiency of the entire pneumatic system.

All gas heat up during compression and cool down during relaxation.

The cooling effect must not be under-estimate. As an example, a typical 200 bar

(atm.) cylinder

empty adiabatically (without thermalization to ambient temperature) gives at the

end an air so cold

that its volume is then a 1/4 of that of the air once back to the ambient

temperature (isothermal relaxation).

In those temperature conditions at the entrance of a pneumatic motor, the

efficiency is catastrophically low

and the lubricant solidified, increasing considerably the internal engine

friction...

Generally, the reversibility of the compression - relaxation cycle reduces with

an increase in pressure,

which favours for high efficiency consideration the use of the lowest design

pressure possible.

The measurement of the exhaust temperature gives generally a good indication of

the efficiency,

since the minimum of energy lost into the environment correspond to

an exhaust temperature equal (neither inferior, nor superior) to the ambient

temperature.

This condition can be achieve by a slight heating (solar) of the gas before its

entry into the pneumatic motor.

Since the Quasiturbine rotates from pressure as low as 1/10 of atmosphere (bar)

(one psi !),

one understand why the Quasiturbine is so well adapted to high efficiency

system...

Attention : Steam Quasiturbine

has provision for thermal expansions and special care to corrosion.

For this reason, the Steam QT will not at this time perform efficiently in

pneumatic mode engine.

On its part, the pneumatic Quasiturbine will cease if used with steam without

modifications.

Similarly, this pneumatic version must not be used with incompressible fluid

(hydraulic mode)

without having been first modified to avoid seals hydraulic lock.

One day, theses specificity will probably be incorporated in all the

Quasiturbines ?

Steam engine - Product description

:

The Steam Quasiturbine research application prototype is very similar to the

pneumatic one, except for lubrication and corrosion consideration.

Attention : Steam Quasiturbine

has provision for thermal expansions and special care to corrosion.

For this reason, the Steam QT will not at this time perform efficiently in

pneumatic mode engine.

On its part, the pneumatic Quasiturbine will cease if used with steam without

modifications.

Similarly, this steam version must not be used with incompressible fluid

(hydraulic mode)

without having been first modified to avoid seals hydraulic lock.

One day, theses specificity will probably be incorporated in all the

Quasiturbines ?

|

It is the buyer and/or operator

responsibility |

- These prototypes are experimental and are not intended for commercial use.

- They require some monitoring and maintenance (like lubrication).

- The must be operated under the constant supervision of qualified adults.

- Anchor the prototypes well before each start-up.

- Never exceed the limits and suggested conditions of operation.

- Wearing safety glasses, mask and fastener hair is recommended.

- The demonstration room must be well ventilated.

- Check the tightening of the bolts and adapters. Be wary of the rupture

or the decoupling of any of the flexible hoses.

- Have a distant valve allowing to cut the air flow (nitrogen / steam) as

needed.

- Particularly during grinding, it can happen that the

rotor be at a dead point,

and refuses to turn when the pressure is applied.

This situation is unstable and call for urgent pressure release.

Then and in absence of pressure, slightly turn the rotor and pressurize

it again...

- During the demonstration, nothing should approach the engine

and makes the observations at a distance of 50 cm (20 po.) or more.

-

Always remain vigilant!

Leave a message at quasiturbine@promci.qc.ca to

discuss Leasing or Buying,

indicating pneumatic (which gas ?) or steam, and the needs in torque, RPM and

power in known.

(Quasiturbine Tronçonneuses Inc. will not reveal the identity of prospects or buyers, but

those ones are free to do so).

* * * * *

Internal combustion engine - Product description : (Not available for now).

Stirling engine - Product description : (Not available for now).

Quasiturbine Tronçonneuse Pneumatic QT50SC

(In practice, over 5 HP on a 100 psi air line)

Chainsaw

(pneumatic air motor or internal combustion) will not be available before some certification.

* * * * *

Even if the Quasiturbine team do not generally participate

actively to engine integration projects,

you are invited to consult the

A summary of ENGINE INTEGRATION METHODOLOGY

TO A ROLLING FRAME (Including an example)

at :

quasiturbine.promci.qc.ca/QTChassis.htm

| Return to main menu |

Quasiturbine Tronçonneuses Inc.

Casier 2804, 3535 Ave Papineau, Montréal Québec H2K 4J9 CANADA (514) 527-8484

Fax (514) 527-8484

http://quasiturbine.promci.qc.ca

quasiturbine@promci.qc.ca