|

|

Many new engine concepts are just

piston equivalent engines.

An equivalent engine is fine, but not enough to justify a paradigm shift.

The Quasiturbine has superior characteristics that no other engine has yet!

Theory - Quasiturbine Specifics

Why Is QT Exceptional?

This is probably the most intriguing page of this website, the most

unpleasant to read, the most hermetical, but the most promising of all. The Quasiturbine is universal in relation to

energy sources:

Liquid and gaseous fuel, hydrogen, steam, pneumatic, hydraulic... and offers

un-equal versatility.

|

Typical comparison:

Engine displacement versus the Total engine volume

4 strokes engine type

Unit displacement

Engine volume

Piston

1

15 to 20

Wankel

1

5 to 7

Quasiturbine

1

1.3 to 2

The Quasiturbine is a positive

displacement turbine

with a total displacement almost equal to the engine volume

(Imagine one day, a 3 liters car engine into a

3 liters volume!)

|

The Quasiturbine can be operated at

lower compression ratio, in standard Otto and Diesel cycle modes,

and the Quasiturbine AC (with carriages) has the fastest pressure ramp.

At low load factor, the intake depressurization of the Otto cycle

dissipates power from the engine since the throttle valve is almost closed and

the descending piston acts as a clogged vacuum pump against the atmospheric pressure,

which vacuum is subsequently partially destroyed

by fuel vaporization during the compression. Due to this effect, the

engine in Otto cycle opposes to all RPM revolution increase (well known as the

engine compression braking) and this intrinsic resistance to speed augmentation

is compensated by a constant and important fuel consumption. The detonation mode does not use any

throttle valve and accepts without constraint all available air at atmospheric

pressure (similarly as the Diesel, where the pressurization energy is restituted

at the time of relaxation). For this reason, the efficiency at low load factor

of the photo-detonation engine is twice that of the conventional Otto cycle, and

considering that the load factor of a car is in average of about 10 to 15%, this

is not a small difference (saving is still superior in the traffic jams...). The most important revolution of the

Quasiturbine comes from its characteristics permitting detonation which occurs at slightly higher

compression ratio than the

thermal ignition, designated in the US as "Homogeneous Charge Compression

Ignition" HCCI combustion, in Europe

as "Controlled Auto Ignition" CAI combustion, and in Japan as

"Active Thermo Atmosphere" ATA combustion. Even if the subject

passionates the researchers, the thermal and photonic ignition control in the piston is still

an unsolved problem, and possibly a dead-end that

the Quasiturbine does overcome!

But why does the Quasiturbine stand what the piston can not tolerate?

Simply because kinetics with vicinity of the "piston" TDC and the "QT-blade" are diametrically opposed,

simultaneously in volume and speed. In volume, because the piston passes at the

TDC at almost constant volume, whereas QT-blade passes the TDC with a

discontinuity in volume (slopes linear quickly ascending and

downward). In speed, because the

piston passes at the TDC with a discontinuous speed (deceleration, stop, and acceleration in opposite piston),

whereas the QT-blade passes the TDC at constant speed (with moreover a null radial component). Two mechanical considerations

rise directly from these physical characteristics.

-

Firstly, the piston is rising (kinetic ascending) when

the early photo-detonation comes to strike it (kinetic downward), and as

two objects moving in contrary direction hit violently, the piston

badly resists, whereas the QT-blade passes the TDC at

constant and null kinetic radial moment.

-

Second, the short pressure impulse of Quasiturbine

retains much less longer than the long sinusoidal impulse of the piston,

and consequently the QT-blade tires much less. Centrifugal force on the

blades of Quasiturbine also helps to contain high pressure.

For all those reasons, and considering what it is intended to achieve,

the Quasiturbine cannot be considered as a rotary piston engine.

Piston paradigms do not apply to the Quasiturbine!

Principle While most rotary engines use the principle of volume variation

between a curve and a moving cord, this new engine concept makes use of a

"four degrees of freedom X, Y, q, ø" rotor, trapped inside an internal

housing contour, and does not require a central shaft or support. The

Quasiturbine is a concept which improves the conventional engines in 2

ways : in reducing the dead time, and in making better time management in

the engine strokes. Keeping in mind that gas turbines have a compression

turbine and a power turbine, and that the Quasiturbine results from a

research initiated in 1993 aimed at unifying those two turbines into one

entity (blades of which work alternatively as a compression turbine and a

power turbine). Consequently, it should not be surprising that the

Quasiturbine shows similar characteristics with those of the conventional

turbine. On the other hand, engines that use crankshaft generate

sinusoidal volume impulses during which the piston stays a relatively long

time at the top while it decelerates and reverses direction, and stays

briefly at mid-course, which is contrary to the logic of a better engine

(Compression impulses should be as short as feasible, and the stay at

mid-courses the longest possible for a better mechanical energy

extraction). The Quasiturbine is also revolutionary because it generates

this new type of volume impulses differently from the crankshaft engine! (In

fact, the Quasiturbine asymmetry permits to devolve less time to the compression and exhaust strokes,

and more time and volume to the intake and expansion strokes). Furthermore, the

Quasiturbine brings the engine dead time to zero.

Consider the following figure where the Quasiturbine rotor confinement

"Saint-Hilaire skating rink profile" (From the name of the physicist who

first calculated this profile) is presented with the minimum and maximum

diameter circles and an elliptic reference profile.

Quasiturbine rotor confinement "Saint-Hilaire skating

rink profile"

This configuration displaces its entire volume every

revolution,

WHAT ABOUT A 3 LITERS DISPLACEMENT ENGINE

INTO A 3 LITERS ENGINE VOLUME!

Eccentricity can be still higher, but for current devices,

a less eccentric

Quasiturbine

is easier to built,

and well able to exceed piston engine performance.

High lozenge eccentricity (here 0,578 for the model QTSC - without carriage) may not be the most practical case

(corner angle goes from 90 - 30 to 90 + 30 degrees),

but it does emphasize the Saint-Hilaire skating

rink profile. Still higher eccentricity does make the straight top and bottom legs to become

convex, while still acceptable confinement profile.

The four pivoting blades rollers and the central annular supporting track are

also shown.

Careful observation near the TDC (top dead center) shows a triangular like

chamber.

Power on Demand

Multi-pistons engines have an advantage over a single larger piston in term of

torque continuity, vibrations and convenient packaging. In principle, there is no advantages

to stack many QT

on a same shaft, preferring a proper parameters selection at design.

However, because the Quasiturbine shaft is no-crank, multi Quasiturbines stack

can easily be done

with a simple ratchet coupling on a common shaft. Contrary to multi-pistons

crankshaft which can

not provide full power at both crank ends (because of crank torsion

deformation), this is not a

limitation to multi-QT stack.

Multi-QT stack would further allows power on demand by firering more than one QT

only when needed,

the other ones staying at rest, for the highest efficiency! (varying the number

of firing pistons

imposes to keep the dead pistons running free).

Quasiturbine Uniflow Characteristic

In most reciprocating piston engines, the steam reverses its

direction of flow at each stroke (counter-flow). By entering and exhausting the

cylinder by the same port, the cylinder valve and walls are cooled by the

passing exhaust steam, while the hotter incoming admission steam is wasting some

of its energy in restoring the temperature. Some energy is further lost in

reversing the motion momentum of the mass of steam within the piston. The aim of the piston uniflow is to

remedy this defect by providing an exhaust port at the end of the stroke, making

the steam flowing only in one direction, but has the inconvenience of

recompressing some residual cylinder steam. Quasiturbine is a uniflow engine,

with the further advantage of not recompressing any residual steam, resulting in

superior energy efficiency. Recompressing residual steam means some

reversibility losses, and the pressure increases makes a substantial restriction

to the initial steam flow into the chamber, not to ignore the truncated cycle

near bottom dead center - None of this with the Quasiturbine.

Specific Quasiturbine Elements

1 - Rapid transition at dead points: The "Saint-Hilaire skating rink

profile" (specially the model QT-AC with carriages)

allows the fastest possible transition around the top dead center (TDC). Considering that

the successive seals move in the inverse direction, all improvement to the rate of radial

variation is doubled in effect. In this case, a rotor move of no more than 10 degrees

brings the engine at 50% of its maximum torque.

2 - Torque continuity: Contrary to most rotating devices which are

progressive, meaning that the torque is nil at TDC and increases progressively until a

maximum is reached, the Quasiturbine "Saint-Hilaire skating rink profile" rapidly reaches the maximum diameter, and then follows it with accuracy on its

entire length. The continuous

combustion (flame transferred from one chamber to the other, not possible on the Wankel

engine) permits optimization of torque continuity. In assembling 2 units with a phase

difference of 45 degrees, one assures a positive torque for any angle of the engine shaft,

even at zero rpm. Lets recall that the Wankel fires 3 times per rotor (not

shaft) revolution (each space by a 30 degrees engine dead time), but since the

main shaft rotates 3 times faster than the rotor, it does fire only once per

shaft revolution, and has not this kind of continuity offered by the

Quasiturbine.

3 - Asymmetric cycles: The Quasiturbine furthermore benefits from the

fact that it looks much more symmetrical at first than it is. In fact, at top dead center

(TDC) the carrier seals are not 90 degrees apart, but are, however, in exact opposition.

The A and B seals are 77.7 degrees apart, while the B and C seals are angled 102.3

degrees. Consequently, due to the carrier rocking effect, the linear distances between

seals vary continuously, and a radial analysis does not permit a correct understanding at

full performance (The Wankel has its 3 successive seals at constant and equal

linear distance). A further asymmetry comes form the fact that the fixed intake

and exhaust ports can be located away from the middle cycle, giving more time

for intake and combustion gas expansion, and less time for compression and

exhaust.

4 - Comparison with the Wankel Engine -

See

quasiturbine.promci.qc.ca/ETheoryQTVersusWankel.htm

5 - High compression ratio: At the design parameter selection level, rotating

engines generally present a dilemma. If one wants to increase the compression

ratio, the intake volume has to decrease to an unacceptable level, thus imposing

large engine dimensions. The Quasiturbine does not present this dilemma, and

permits construction of a compact detonation or diesel engine. One understands

from #3 that the compression and exhaust is done on a 77.7 degrees range, while

the expansion (intake) occurs on a 102.3 degrees range. This asymmetry (impossible

in piston engine or conventional rotating device) brings the seals closer

together to give a higher compression ratio and allows the maximum extraction of

energy by an extended expansion cycle.

6 - Leakproof: The Quasiturbine does not have the critical leak proof

problem of the Wankel. The Wankel must make use of 3 seals at the triangle peaks

(Apex), which meets the engine profile with a variable angle on both sides of

the perpendicular (-60 degrees to +60 degrees). Since the Quasiturbine seals are

seated on rocking carriers, they are perfectly perpendicular to the engine

profile at all time. Furthermore, it should be noted that if the carrier wheels

are tight fit into the carrier, the wheels themselves are contributing to seal

the two consecutive chambers (the spring seal being complementary). Notice the

advanced mid-carrier "split seal" design suitable for very demanding situation

(like combustion engine) making use of a sloped groove and the internal pressure

to help maintaining itself in place at all time.

7 - Zero vibration on the shaft: The Quasiturbine is a true rotating

engine with a stationary gravity center during rotation devoid of any vibration on the

shaft (however like any other engine it is subject to unidirectional counter-torque

impulses). On the other hand, the Wankel is a "rotary piston" engine that is subject to a

constant circular vibration. It may be interesting to note that the Quasiturbine "Saint-Hilaire

skating rink confinement profile" is much more difficult to calculate

than the Wankel profile. Since there is no formula, a computer program needs to deal with

this difficulty.

8 - Fast acceleration: Due to the absence (and no need) of the flywheel and due to its low intrinsic inertia, the Quasiturbine is capable of fast

accelerations, including at low rpm. This quality makes it a "nervous" engine

and susceptible to please amateurs of sport engine devices. In comparison, the Wankel has

an important eccentric triangular mass which adds to the inertia and limits its

accelerations. Furthermore, the Quasiturbine can be started using compressed air from a

reservoir, pressure filled from the exhaust gases (A lever can be used to place the rotor

in the optimum initial position).

9 - Construction and reliability: The rotating engines are generally

comprised between a robust external profile and a central shaft seated on strong bearings

which are able to take the load on the shaft created by combustion pressure. For its part,

the Quasiturbine requires only a robust external profile on which the combustion pressure

load also applies; the central shaft is elective and only dedicated to torque transfer

when required. Furthermore, contrary to the Wankel, the Quasiturbine does not need any

synchronization gears (complicated and costly to built, and subject to lubrication and

weariness!), nor any spark plug synchronization. Conventional engines have achieved

excellent reliability considering their pumps, camshaft, rockers, push rod, springs,

electrical distribution... Having none of these devices, the Quasiturbine is then easier

to build, and eventually considerably more reliable (especially if the decision to use the

continuous combustion option is made). Having a low RPM, the Quasiturbine has a better

resistance to wear out and last longer.

10 - Energy savings: The Quasiturbine allows important energy savings

without having pretensions of a better thermodynamic performance than any other engine

(remember that 4-stroke pistons are propulsive only 19% of the time, and

dragging the rest 81% of the time). In fact, the ability of the Quasiturbine to generate a strong

and continuous torque at low rpm permits in numerous applications including

transportation, the suppression of the heavy and costly gearbox that consumes between 8

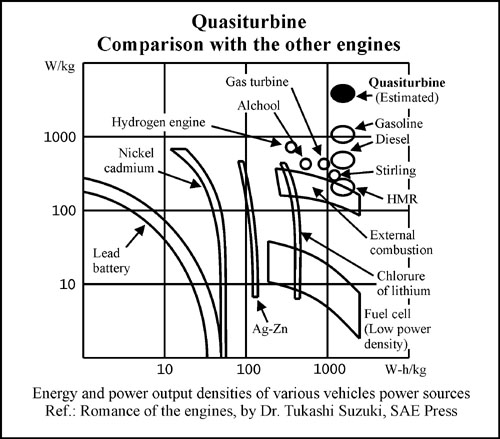

and 12 % of the energy. Furthermore, the best power to weight ratio of the Quasiturbine

(to which the flywheel suppression contributes) gives rise to lighter vehicles (also due

to the suppression of the gearbox) and fuel cost efficiency. The fact that the

Quasiturbine does not require energy consuming peripherals (pumps, camshafts, push rods,

valves...) also constitutes a gain at the level of energy efficiency. (See High-tech

for the detonation mode). Furthermore, the rapid expansion volume just after T.D.C. allows

to extract more energy from the initial hot gas with 3 advantages: thermodynamic

exhaust cool down, less heat transferred to the engine bloc, and less NOx

production. Energy efficiency is related to all the following :

- Thermodynamic (gain from early and late mechanical energy extraction)

- Thermal (smaller heat flux and cooler operation)

- Friction (the product friction X displacement is lower that for the piston)

- Peripheral accessories (gain because of no camshaft, valve, push rods ...)

- Peak power (only 20% higher that the mean power, compare to 7 times for piston)

- Shaft RPM harmonics (which are very low - no need of flywheel to average)

- Gear box saving (8 à 12 % energy saving by not using gearbox)

- Long life time (wear is measured in number of passages, low RPM means long life)

- Intake efficiency (piston has poor sine wave intake characteristics)

- On board application saving (lighter vehicles ... means saving over 10 years!)

- Fuel additives (Quasiturbine requires much lower octane level)

- Environment (fuel savings and much less NOx production)

- Vibration zero (source of $ billions of damages and corrosion acceleration)

- Cumbersome (4 times less than the piston engine)

- Weight reduction (5 times less than the piston)

Note on the Pressure-Volume diagram: The engines present cyclic

characteristics which are particularly well established by a close curve on a

pressure-volume diagram. In the case of the piston where the pushing surface is

strictly equal to the surface generating the volume, the surface enclosed in the

close pressure-volume diagram curve is then proportional to the work (energy)

done by the gas.

11 - Environment: It is well known that the 2 cycle engines are light and

nervous, but also very polluting. The reason for this pollution is due to the

fact that, in the 2-stroke engine, the exhaust gas are blown out of the engine by

the incoming intake mixture, and in order to have a maximum power, part of this

intake mixture passes directly to the exhaust manifold without having been

burnt. In the Quasiturbine engine, intake mixtures never come into contact and

neither are "pushing" the exhaust gases. Consequently, the Quasiturbine has

power characteristics of the 2 cycles engine, while meeting the excellent

exhaust combustion of the 4 cycles engine. For environmental reasons, we will

most likely stop using actual versions of the 2 cycles

(fuel injection being a possible improvement). The Quasiturbine engine will then

be one of the few alternatives to consider !

12 - Variety of fuels: In engine mode, the Quasiturbine is an excellent

pressured fluid energy converter (pneumatic motors, steam engines, zero leak

hydraulic engine for water fall, etc). Large units may be used to produce

electricity in coal or heavy oil thermal power plants, or to transform in

mechanical energy the residual steams of industrial processes. In addition to

the use of conventional liquid petroleum fuels, the Quasiturbine can in

principle make use of (if adapted) a wide variety of fuels from methanol to

diesel oils, including the kerosene, the natural gas and eventually the hydrogen

(See High-tech). About using computerized carbonation, one must realize that the

flow in the intake pipe is very continuous, and not shopped like in the piston

engine. In fact, the intake pipe load factor is expected to be 3 to 5 times

better, so that continuous fuel injection is appropriate without any

synchronization.

13 - Electrical integration: The Quasiturbine permits for the first

time a complete monolithic integration of the electric generator with a fuel engine (much

in demand for hybrid applications, and without vibration). Due to the fact that the center

of the Quasiturbine is free, the fixed electrical components can be simultaneously on the

central core, and on the peripheral stator. Only the intermediary zone is in rotation.

Reciprocally, if the electrical components make a motor, the Quasiturbine becomes an

integrated electrical pump-motor, or a bi-energy power plan.

14 - High-tech: Hydrogen is, without a doubt, the highest in high tech

fuels. However, high inflammability of hydrogen imposes a stratifiable intake chamber to

the engine distinct from that of the combustion chamber (which disqualifies the piston

engine) . The Wankel engine success for direct hydrogen combustion comes for its

intake and combustion stratification, which results mainly from early intake (like

Quasiturbine) and its excessive volume during expansion (with an efficiency lost). The

Quasiturbine engine offers the same hydrogen advantage, without the lost of efficiency and

hydrogen oil degradation (oil free). The Quasiturbine meets the

fundamental criteria imposed by the "hydrogen" engine of the future (cold

intake area, stratified intake, reduced confinement time, low sensitivity to detonation,

less pollutant, robust and energy efficient), and even surpasses the Wankel in

this respect, since the intakes are separated by 3 strokes instead of two.

15 - Oil free engine, compressor and pump: In the

Wankel engine, the oil pan is also mandatory for shaft, bearings, gears lubrication and

thermalization. In the Quasiturbine, oil is not a cooling agent, and is only required at

seals friction interface. Use of ceramic or high tech seals can make the Quasiturbine an

oil free engine (Thermalization being done by the contact of the carrier wheels).

Furthermore, since hydrogen degrades all oil, lubrication free must be developed for

hydrogen engine any way. For units built with conventional materials, a lubricant can be

added to the fuel or the vapor. Notice that units with exhaust in the lateral covers (and

not radially) are true centrifuge oil traps, and the needs of lubricant are consequently

minimal.

16 - Combustion chamber of superior geometry: The combustion chamber

can be positioned at several locations (radially or laterally). We suggest that the

chamber be located in a tangential median cut in the rotative blade filler tip such that

at top dead center, it is squeezed between the 2 carriage rollers and the Saint-Hilaire

profile on which the sparkplug is located, all such to contain over 80% of the

gaseous mixture in a rounded corners cube like shape (at top dead center, the

ratio of the visible surfaces to the combustion chamber volume is comparable to

the piston. The chamber can be made semi-spherical, cylindrical or else ...).

When at bottom dead center, this cut has the advantage to prevent the filler tip

to devise the chamber in 2 parts, and insure complete chamber ventilation in the

exhaust.

17 - Wider power range than conventional turbines: The Quasiturbine

operates according to hydrostatic principles, by opposition to conventional turbines which

operates along hydrodynamic principles. Just a word here, to recall that the conventional

gas turbines are conceived for a precise aerodynamic flow, and do not offer a wide power

range with reasonable efficiency. For its part, the Quasiturbine does not use aerodynamic

flow characteristic on the blades, and keeps its excellent efficiency on a wide power

range. It is the same when the Quasiturbine is propelled by steam, compressed

air, or by fluid flow (Plastic Quasiturbine for hydro-electric centrals, etc).

Furthermore, the Quasiturbine does not require superheated steam, neither dry

steam, and is particularly suitable for energy recovery, cogeneration, or steam

pressure reduction station.

18 - Possibility of 2-stroke Quasiturbine: Each chamber of the

Quasiturbine passes across 4-stroke: intake, compression, expansion, exhaust. In the 2-stroke piston engine, an external blower is used to insert the combined exhaust and

intake strokes at the end of the expansion and the beginning of the compression (those last

ones being shortened). In principle, the same can be done with the Quasiturbine, which

would give two simultaneous combustions in the top and the bottom chambers (those

chambers can be interconnected by a pressure equalizer tube), canceling out the net load

of the rotating blades on the carriers. As it is for the piston engines, this would

permit to almost double the power, against a deterioration of the efficiency and the

percentage of burned gas (pollution). The 2-stroke Quasiturbine would be to our

knowledge by far the highest power density engine in weight and volume.

19 - High power density: In order to achieve high power density (in

volume and weight), the concept and design of engine must make sure that all components

are continuously essential at all time. For example, the pistons of a car engine being

independent, each piston is useful while propulsive (17% of the time), but present a rest

and an unfortunate drag for most of the time (83%). In the Quasiturbine, all

components are continuously essential at all stage of operation, and none experience any

dead time. Associated to the continuous combustion, the Quasiturbine is one of the best

candidates in the race for high power density engine. This exceptional characteristic has

a counterpart: as the material never rest, it must be of the best quality.

20 - Consideration on friction: Fortunately, the modern materials

permit to reduce considerably the friction, which still is the no. 1 enemy of engine

designers. The seal's friction on plane surface of the Quasiturbine can be reduced by

using the well known conventional solutions. The blade's rotary joints pose a somewhat

different problem, but simple nitrogen treatment seams generally appropriate. Finally, the

carrier seat on the rotary blade joint can be more critical. In the case where similar

pressure are used in the two independent circuits of the Quasiturbine (case of

compressors, steam and pneumatic engines, pumps, QT 2-stroke combustion engine), the

opposed pressurized chambers tend to cancel the net load of the rotative blades

on the carriers (at least in the square configuration), and no particular

measure is then required at the carrier-blade interface.

21 - Bigger is better: The Quasiturbine in hydraulic,

pneumatic or pump mode is little sensitive to the size, and does not present a critical

threshold (except for large viscosity). It is different with fuel combustion mode

because one must simultaneously manage the high pressure, the intake vacuum, and the

combustion conditions. One must generally consider two intrinsic factors : the leak ratio

= (total length of the seals / volume) which decreases as the square of the size, and the

contact ratio = (surface of the chamber / volume) which decreases as the inverse of the

size and the confinement time. As those 2 negative factors decrease with the engine

size, it is then relatively easier to run a large unit! (This is generally

also true for other engine concepts). On the other hand, for every fuel considered, the

combustion chamber must simultaneously have the minimal compression ratio and the minimal

volume required, conditions which are easier to realize with large units.

22 - Self dynamic torque regulation: While

rotating, the mass of the piston must be accelerated and decelerated by the

crankshaft mainly in the first and last quarter from TDC to TBC, at angular

position where the torque generated is low, which amplified the rotational

harmonic on the crankshaft. By opposition, the Quasiturbine rotational speed

slows down when extending in lozenge and accelerates when retracting into the

square shape, which means that the rotor tend to accelerate most near the dead

square position where the torque generated is minimum, which self dynamically

reduces the engine RPM fluctuations.

23 - Ideal motor for hybrid vehicles: The WHEEL

MOTOR is an element of the hybrid vehicle traction group, as is the necessary

"onboard generator" which recharges the batteries. We think that the

QUASITURBINE is the ideal motor for this indispensable "onboard generator" in

hybrid vehicles, since it meets all the required qualities :

- Zero vibration (the small piston engines are generally too shaky !)

- Compact (5 times less cumbersome that a piston engine)

- Lighter (5 times less heavy than an equivalent piston engine)

- Less noisy (without muffler : 20 times less than an equivalent piston engine)

- More efficient and less pollutant (500 times less NOx ?)

- And more ...

24 - Other applications: The data and most preceding comments have been

verified, when possible, on demonstration prototypes. These

characteristics benefit to all Quasiturbine applications, which include pressured fluid

energy converters (pneumatic, steam...), combustion engines, compressor modes, pumps mode,

and others.

More Technical

Why is the Quasiturbine

exceptional?

Photo-detonation engine

|

|