Application advantages could be as

precious as intrinsic engine ones.

Engine efficient is just the beginning of a saving cascade.

Quasiturbine offers optimum efficiency with a variety of fuels and modes.

Quasiturbine Efficiency

About QT Efficiency - See Also:

Specific efficiency are presented on corresponding

engine / expander description page.

Internal combustion is

completed by a presentation at

quasiturbine.promci.qc.ca/ETheoryDetonationEngine.htm

Gas expander theory and efficiency is covered at

quasiturbine.promci.qc.ca/EProductQTCutOffValve.htm

Where is the Energy Wasted?

Engines do not create energy, they only transform it

into mechanical energy with some inevitable losses. Physics imposes

thermodynamic losses to energy transformation which cannot be circumvent,

but engine losses are more important than the minimum the physics is

telling us...

In internal combustion engine, the energy is lost in

several ways. Vacuum intake of the gas engine is responsible for about

half of the gas consumption in today vehicle (hybrid concepts are trying

to harvest some of that, while detonation engine could eliminate this

loss). Inhomogeneous diesel fuel mixture is catastrophic to combustion.

Partial combustion in gas engine is also a lost. Internal engine

accessories like cam shaft and valve train are reducing the net available

engine power. Thermodynamic imperfect machine cycle is also a substantial

lost. Lubrication friction is taking an other 3%. Scaling down engine is

not helping either...

Large utility plants convert energy more efficiently

than small distributed units and should be favored when possible. The

detonation Quasiturbine engine is one of the very few long term means to

match utility efficiency the distributed way, while being as chemistry

clean as possible.

Internal combustion residual pressure:

Once the piston get to BDC, it cannot extract any further pressure energy.

However, the combustion gas pressure is still present and flushed out. At

that time, back pressure has not negative effect on the piston while in

BDC. This is the residual combustion pressure the turbo (or pressure

exhaust QT) is designed to recover, and fortunately, higher is the initial

piston mixture pressure (higher engine power), higher is this residual gas

combustion pressure. Same happened within IC Quasiturbine.

Engine Exhaust Heat Recovery:

By placing a hot Quasiturbine into or around an engine exhaust pipe, and

injecting pressurized hot water (steam keep in the liquid state for better

heat transfer), some heat can be recovered into mechanical energy.

Stirling and short steam circuit Quasiturbine could do similarly!

Relative to the pressure flow energy conversion role

of the Quasiturbine, the efficiency (not an absolute efficiency) is given

by the (power or torque obtained) divided by the (power or torque which

could be obtained according to formula), which is typically between in the

80 % efficiency as of 2009.

A Cascade of Savings

Engine efficiency is a large

domain of activity which extends far behind engines. The presence of an

engine in a vehicle adds accessories and weights which have to be carried

by the power of that same engine (the net usable power is reduced by the

presence of the engine itself). The presence of the engine is a necessity,

but also a factor of inefficiency. The ideal vehicle would not bother to

have an onboard engine! This shows that not only engine efficiency is

important on the bench test, but must also reduce to the minimum its

self-inefficiency in application. It would be worthless to have a 70%

efficiency gas engine for mobile application, if such a 30 HP engine would

weight 3 tons! This is one of the paradox of today hybrid vehicle concept:

How much additional equipment can be added to a vehicle to reach the point

where this equipment has worthless net saving effect in actual

application?

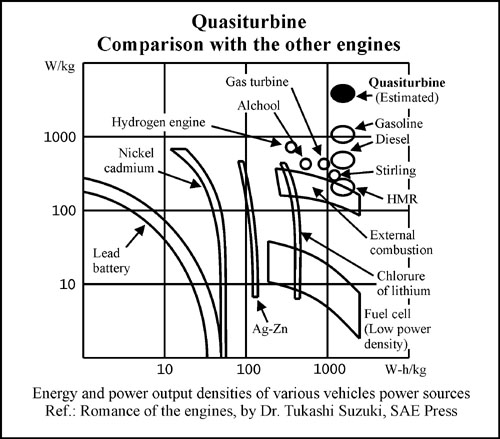

Because the Quasiturbine reduces the weight of typical vehicle power

train by over 50%, it does not have to claim any extra efficiency on the

test bench to be most valuable. Such a reduction of weight on the lifetime

of a vehicle means substantial reduction in power demand, and consequently

in fuel.

However, the Quasiturbine has several intrinsic efficiency characteristics

which add up, and reduce the engine energy lost in several ways:

- Because it does not have internal accessories to drive, like the

piston cam shaft and valve train, additional energy is available to the

end users.

- Because of the shaping of the volume pressure pulse, the

thermodynamic of the Quasiturbine can be far superior.

- Because the engine weight is about 1/4 that of a piston, energy

saving can be substantial in many applications.

- Because the Quasiturbine is a high torque low rpm engine, much less

or no transmission gears ratio are needed with corresponding efficiency

increase.

- Because the Quasiturbine can be of large size, it is an efficient

alternative to utilities for efficient energy conversion (steam) in

electricity or from co-generation.

- Because the Quasiturbine (AC model with carriages) has the potential

to run in detonation mode, it will not have the low power penalty of the

Beau de Rocha (Otto) cycle, which can provide a 50% energy saving in

transportation application (much superior to hybrid concepts).

Multi-fuel capability is also an important efficiency factor permitting

to use the most pertinent local combustible. Hydrogen high compatibility

is also of consideration for the future.

Applications

Such small and efficient Quasiturbine steam engine makes mobility possible.

Thermal solar steam could drive a Quasiturbine. Solar concentrator could

directly heat up a Quasiturbine engine bloc, which would act as evaporator,

super-heater and motor! It could also be used for small geothermal or industrial

heat process.

At home, combine electricity and heating would be possible from several

sources, sometimes with complementary higher temperature source.

Quasiturbine Stirling could be made cylindrical and be inserted directly into

the chimney for optimum heat recovery.

Engine Exhaust Heat Recovery:

By placing a hot Quasiturbine into or around an engine exhaust pipe, and

injecting pressurized hot water (steam keep in the liquid state for better heat

transfer), some heat can be recovered into mechanical energy. Stirling and short

steam circuit Quasiturbine could do similarly! Same technology could apply to:

Industrial exhaust gases heat recovery

industrial furnace heat recovery

Industrial process heat recovery

Chimney or stack heat recovery

Waste heat recovery

Solar heat recovery

Geothermal heat recovery

Thermal nuclear heat

ORC (Organic Rankine Cycle)

Engine suitable for ORC (Organic Rankine Cycle) in Solar, Geothermal and

Waste Heat Recovery.

Efficient at All Loads

The benefit of power modulation is precious. Pneumatic, steam or

combustion turbine engines all have one major limitation: Their efficiency

depends of the load, the rpm, the power... They have to be operated at

their design condition to meet their optimum efficiency at a given working

power. Because the Quasiturbine is not an aero- or hydro- dynamic engine,

but a static pressure type of engine, it has an optimum efficiency on a

large range of power, load and rpm. This allows for efficient uses in

power modulation applications with optimum energy saving and efficiency.

The Quasiturbine is consequently a superior gas expander and most suitable

for efficiency difficult steam co-generation projects.

Piston Beau de Rocha (Otto) gas engine and the diesel engine have

similar optimum power regime limitation. Only the detonation engine has

not.

Quasiturbine as an Immediate Solution

Engines are at the end of the energy chain and they affect the most the

energy users. More efficient engines not only save fuel, but any bit of

saving has direct amplified impacts on all anterior stages of the energy

cascade and industry.

Click here for a 2000 pixels

high resolution image

The Quasiturbine in Beau de Rocha (Otto) cycle is a

relatively simple technology which could be widely used within a few years

with substantial efficiency benefits over the piston engines in many

applications. Other claimed advantages include high torque at low rpm,

combustion of hydrogen and compatibility with detonation mode.

A lot of research are going on to increase the efficiency on the long term

with piston, hydrogen, fuel cell... Hybrid concepts are ways to harvest

part of the "low power efficiency penalty" of the piston engine used in

vehicle, but counter-productive measures limit the long term perspective

until they could efficiently fuel from the electrical grid. None of these

solutions are short term stable and competitive.

By

opposition to dozens of new engine designs, the most important at this

time about the Quasiturbine is not the actual machine, but the fact that

it does unknot a new field of development and offers means to achieve what

no other engine design has suggested or is able to, and specially for

detonation where piston engine has failed for over 40 years...

Efficiency as Rotary Expander

Gas Pipeline Pressure Energy Recovery - Rotary Pressure Expander

What about an "energy recovery rotary pressure regulator" ? An

interesting application of the pneumatic Quasiturbine is to recover the

pipeline high pressure energy at local distribution stations. Instead of

using a conventional pressure regulator (an energy dissipative device), a

pneumatic Quasiturbine will rotate under the pressure differential and the

flow will be controlled by the rpm, i.e. the torque applied on the

Quasiturbine shaft. It does act as a dynamic active rotary valve. This

way, the Quasiturbine can transform the pressure differential into useful

mechanical work to run pump, compressor, ventilator, electricity generator

or locally convert the energy in high grade heat (better than pre-heating

the gas before that same "rotary expander", to avoid any residual

condensation as done with conventional regulators). Substantial heat is

now given to conventional expansion valve in pure lost, while heat given

to the gas at the intake of a rotary expander is essentially all recovered

in mechanical energy or electricity. Because conventional turbines can not

be widely modulated in rpm and load, they are not suitable for gas flow

and pressure control, while the Quasiturbine is essentially a closed valve

at zero rpm, and has high efficiency at all torque and all flow rpm. With

such a system, any heat added before the Quasiturbine expands the gas and

increases the available volumetric flow with the result that this heat is

converted in mechanical energy with a very high efficiency. All

experimental demonstration has to be done only by gas experts and under

all current rules and regulations. Ignoring gas expansion and considering

only the gas pressure flow, a 36 inches diam. gas pipeline at 700 psi

carry typically a pressure power in excess of 30 MW - 25 millions of

pound-ft/sec - of zero pollution pure mechanical energy almost totally

recoverable through Quasiturbines in the heart of cities and industrial

parks. This is tens of giant windmills on kW-h basis!. A survey (M. Dehli,

GWF Gas-Erdgas 137/4, p.196, 1996) showed that in Germany alone, the

potential for utilizing this pressure in 1996 was 200-700 MW, and the gas

consumption has increased since then... See the

conceptual diagram and a

pipeline technical paper.

Economics: Take any similar fossil fuel

electric generation station, and set the fuel cost to zero, as the

pressure energy recovery does not consume any fuel. It is even better than

renewable, it is free energy, until the utilities start to charge for it,

and make an easy extra income!

Refrigeration: Conventional pressure regulators make all the gas to

expand from the constant high pressure side, and the gas pressure-kinetic

energy at the needle is converted into undesirable heat, reducing

accordingly the amount of cold produced. The Quasiturbine rotary expander

allow for individual chamber to expand at a variable reduced pressure

during expansion, and such reduces the gas kinetic energy transformation

into destructive heat. Furthermore, the Quasiturbine recuperates

mechanically the gas differential pressure energy, which can be used to

run more compressors and make more cold... A double energy efficiency

gains! A single Quasiturbine in tubo-pump (tubo-compressor) mode could

have one circuit used as rotary expander while the other is used to

compress back some of the expanded gas. This offers great enhancement of

thermodynamic cooling machine, and specially in high power LNG - Liquid

Natural Gas liquefaction stations. Of course, this efficiency enhancement

is also available for more modest cooling system and air conditioning

equipments. With Quasiturbine rotary expander, the efficiency of a gaseous

only (like dry air) system reaches almost the efficiency of a phase change

liquid-gaseous system, and sophisticated phase change chemical products

often environmentally unwelcome are not anymore needed.

More Technical

quasiturbine.promci.qc.ca/QTperformance.html

Quasiturbine Rotary Expander

Intake cut off valve

|