Quasiturbine moteur

à hydrogène

Haute efficacité

Admission aspirée en continue à la pression atmosphérique

Potentiellement sans lubrifiant

* * * * *

|

Mars 2003 - Une étude du MIT affirme

: |

Sure there is a place for hydrogen and fuel cells, but not intelligently everywhere...

* * * * *

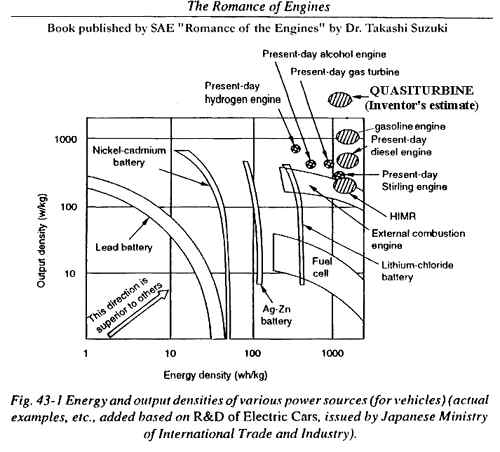

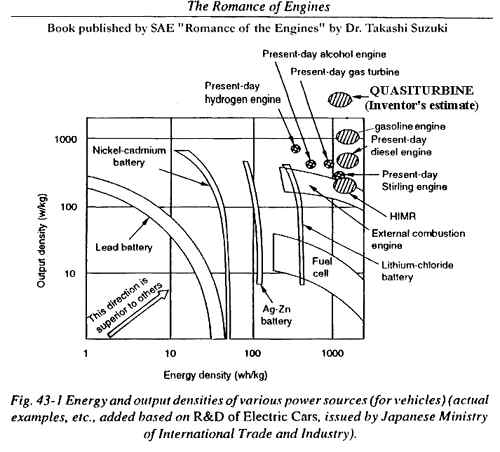

(The RAGON engine diagram)

If hydrogen is going to be widely available,

fuel cells will be a end-user low pollution technology, initially costly on lifetime maintenance.

However, the fuel cell chemistry will not permit

to make very high density power plant in weight and volume (refer to the RAGON

engine diagram),

like it is easily done with internal combustion (IC) engine.

For many applications from chainsaws or motorcycles, to propeller

airplanes,

hydrogen and multi-fuel internal combustion engine will then be most suitable

anyway.

Comment on Hydrogen - Water - Electricity -

Environment

... use electricity to make gasoline...

Water is the end result of hydrogen combustion. In term of

energy, water is like burned hydrocarbon or ash.

The energy content of water is so minimal that no other liquid is better to

extinguish fire!

Making hydrogen fuel from water is energetically the same as making gasoline

back from the exhaust gases (CO2 and water).

Primitive water electrolysers that separate the electrodes using either spacing, asbestos, glass

or wool

are only 50% efficient (half the electricity goes into heat).

Modern electrolysers efficiency is about 70% at a surface current density of 1

amp/cm2,

and get to 81% at lower current densities, but reduces to 50% efficiency at much higher current

densities.

If someone has plenty of electricity and is willing to invest it into making a

fuel,

it would make more sense environmentally to use this electricity into an

exhaust gases reverse process plant,

which would be at least a great way to dispose temporarily of the too abundant

fossil CO2 we have on the planet.

However, nowhere in the world electricity exceeds the demand, and

electricity is the most valuable form of energy.

Using electricity to make a fuel is not very wise. Instead, sell your exceeding

electricity,

use the money to buy and reform natural gas into hydrogen (which can make

sense), and keep the cash savings for other projects!

Manufactured hydrogen has a good potential as fuel, but not by all means.

Hydrogen stores 2.7 watt hours per STP liter and 39,000 watt hours per

kilogram.

Gasoline stores 9000 watt hours per liter and 13,000 watt hours per kilogram.

The energy density of hydrogen is 39,000 watt hours per kilogram, less the containment weight.

Gasoline is 13,000 watt hours per kilogram.

Lead batteries are around 30 watt hours per kilogram.

Best batteries are around 330.

Find out more at: http://www.eren.doe.gov/consumerinfo/refbriefs/a109.html

http://www.eren.doe.gov/hydrogen/faqs.html#howmuch

Isoler l'hydrogène à

partir des hydrocarbures fossiles

fait perdre au bas mot 30 % de l'énergie initiale.

Ensuite, stocker l'hydrogène gazeux est aussi coûteux

en énergie de compression souvent perdue à la détente.

Suite à une décennie exploratoire sur l'hydrogène,

on redécouvrira sous peu que la meilleure façon de stocker l'hydrogène

est de le lier tout autour d'un atome de carbone CH4 , C3H6

...

pour former des gaz liquéfiables ou directement des liquides

qu'on appel hydro- (pour hydrogène) et carbure (pour combustion).

On redécouvrira que nous fonctionnons déjà à l'hydrogène

sous une forme efficace et peu dangereuse !

The difference between liquid and gaseous

fuel in the Quasiturbine ?

Ultimately, all fuels get into gaseous state in the combustion chamber, so one

may be at first legitimate to expect little difference,

but looking at the combustion process itself is not where the answer stands.

One needs to look at the details of the specific engine intake and dynamic.

Because engines generally prefer a near stochiometric mixture

(except for non-homogenious Diesel and homogenious photo-detonation, which works

in excess of air),

the amount of fuel and air should be balanced at intake. Lets consider the

gasoline 4 strokes piston engine.

When the intake valve opens, a fix volume is aspirated.

Since the gasoline intaked as liquid droplets does occupy almost no-volume,

most air available can be intaken from the depressurised intake manifold.

In this regard, the gasoline injectors near intake valves are superior to the

carburetors

in permitting more liquid droplets and less gasoline atomization (vapor),

which explains why the modern gasoline injector engines have a higher specific

power density.

Fortunately with the piston engine, when the intake valve closes, there is

plenty of time for the gasoline droplet to atomize

during compression and later even during the combustion stroke,

because optimum pressure is not required until well pass the TDC (top dead

centre).

However, this droplets intake technique is not without adverse effect on

pollution,

but this slow imperfect combustion saves the engine valves from being torched

out !

By opposition, intaking gaseous fuel which occupied a substantial volume, will

leave less volume available for air intake,

and the engine specific power density will be diminished.

Let imagine someone using for example a liquid nitrogen gaseous condenser near

the intake valve

(not good with hydrogen of course), the gaseous fuel would condense into

droplets at intake,

and a more similar situation to liquid gasoline would be observed.

To make it short, it is not easy to produce the same combustion condition by

intaking liquid or gaseous fuel,

and those condition differences are further apparent in the front flame velocity

(in addition to the specific chemistry characteristics...).

Because of its continuous intake flow and its early and late intake

characteristics,

the Quasiturbine is most able to minimize the gaseous fuel intake penalty.

Where does the Quasiturbine photo-detonation mode stands ?

Everyone has experienced that lens sun focalization can lit a fire.

As the compression ratio of an engine increases, not only the gas temperature

increases, but also the radiation level.

Combustion goes primarily through at least 3 phases :

Primo, at low compression ratio, a hot spot (spark) is required to start a

combustion front flame wave.

This subsonic wave propagate and lit progressively the mixture (this is smooth

deflagration use in our gasoline vehicle).

Secundo, higher pressure will provoke thermo-ignition, which is a very

non-uniform process liting mixture patches,

and inter-patches combustion being driven +/- by the previous describe front

flame wave.

Tertio, still higher compression ratio produces uniform radiation driven liting

process,

which is an extremely rapid volumetric combustion.

In this case, there is essentially no front propagation, just a powerful light

radiation everywhere...

This is the most severe knocking that the piston cannot stand, but it is the

most powerful and perfect way to combust fuel !

In fact, additives used to increase the gasoline octane index

are efficient photon absorbant molecules which prevent this kind of photons

build-up,

and such polluting additives are not needed in photo-detonation mode engine.

Even if shock waves do have the potential to lit a fuel mixture,

photo-detonation does not actually make use of a shock wave within the mixture.

However, the rapid chamber pressure increase does generate a shock wave in the

engine environment,

which could be substantially moderated by a rapid increase of the combustion

volume at that time

(this is what the Quasiturbine does !).

So, why does the piston don't stand the photo-detonation ?

Because it stands high compression near TDC (top dead centre) much too long

before producing useful work at mid-stroke.

And why does the Quasiturbine stand it (particularly the QTAC) ?

Because the volume pulse is 15 to 30 times shorter near TDC, and also because

its higher surface to volume ratio

is moderating the violence of the photo-detonation process, which is almost

independent of the mixture front-wave flame velocity...

Consequently, even if the Quasiturbine can run in conventional Otto mode,

its photo-detonation mode provides the most benefit to fuel efficiency and

environment, both for liquid or gaseous fuel...

The Photo-detonation mode : A necessity for

the hydrogen engine

In order to do work on a piston, the fuel-air mixture needs to burn at a speed

faster than the piston is moving.

Low hydrogen flame speed is a disadvantage shared with most other gaseous fuels.

For comparison, a gasoline-air mixture has a flame front speed

that ranges typically from 70 up to 170 feet/second in IC engines,

while an ideal hydrogen-air mixture has a flame front speed of about 8 feet/second.

An average vehicle engine rotating at 2,000 rpm (33 revolutions per second)

produces piston linear speed of 45 feet/second in the middle-stroke,

which is already 5 times faster than the hydrogen flame front speed !

The fact that a hydrogen-air mixture has a flame front speed of about 1/10

that of a gasoline-air mixture contributes to explain why hydrogen engines only

run at reduced power and low rpm under load.

However, the photo-detonation mode is extremely rapid and totally removes this

limitation.

This is why the photo-detonation mode (not compatible with piston, but with the

Quasiturbine)

is so critical for the future of the hydrogen engine.

Pourquoi la Quasiturbine à hydrogène

est-elle supérieure au moteur IC conventionnel?

http://quasiturbine.promci.qc.ca

Quasiturbine prefers Hydrogen storage in carbon molecules ?

A good way to store hydrogen is to link it with carbon atom.

This can produce either gaseous, liquid or solid

high energy density products most convenient

for transportation and mobile uses.

When needed, just heat up those carbon-hydrogen molecules,

and the hydrogen will liberate.

For energy production, the hydrogen storage in carbon molecules

is forward and most efficient, because in presence of oxygen,

not only the hydrogen separates and burn producing water vapour

(a so low energy contained product, that it is used in fire extinguisher),

but the carbon atoms will also burn, first in CO

(which has about the specific thermal energy content

of the hydrogen), and which can further burn into CO2.

(also a low energy contained product used in fire extinguisher).

You win twice !

Other hydrogen storage techniques do not seem to be as practical.

This hydrogen carbon molecule storage technique is safe and simple,

and has been appreciated by humans for centuries,

under the name of hydrocarbon fuels !

GM and BMW are taking different routes on the road :

- GM has invested heavily in developing fuel cells

to power electric motors in vehicles,

replacing the current internal combustion engines.

- BMW, on the other hand, is studying burning hydrogen

in internal combustion engines as a more practical alternative.

Internal combustion engine are combined hydrocarbon fuels

"hydrogen extractor and mechanical converter" all at once !

... and the Quasiturbine is most appropriate to do just that in vehicles

http://quasiturbine.promci.qc.ca/QTVehiculeE.html

Finally, if breakthroughs are still expected with fuelcells,

the photodetonation internal combustion is also

an expected breakthrough with internal combustion engine

which could save half the fuel now consumed in gasoline vehicles

http://quasiturbine.promci.qc.ca/QTPhotodetonation.html

with substantial environment benefits.

The Best Current present state hydrogen technologies:

Fuel cells, operating on reformed natural gas, will have very low emissions, but

despite some claims of very high efficiency, their efficiency is only about 35%

from raw fuel, and half of that in small portable electric motor units (efficiency

fall when getting near maximum output power). Furthermore, they are not readily

available for high power output plants yet now a day, and they are far from

matching the Combined Cycle Gas Turbine CCGT efficiency, which reaches about 55%

(58 to 60% according to

http://www.fossil.energy.gov/techline/tl_ats_ge1.shtml

or

http://www.energyusernews.com/eun/cda/articleinformation/coverstory/bnpcoverstoryitem/0,2582,6779,00.html

).

Hydrogen is not easily usable in conventional internal combustion IC engine due

to its high inflammability (See the INTERNATIONAL ACADEMY OF SCIENCE -

Hydrogen combustion and backfire http://www.science.edu/tech/h74001.htm

) and lower atmospheric pressure specific energy (30 to 50 %

power drop), and generally does require sophisticated and costly synchronized

gas injectors. However, the IC efficiency is potentially competitive.

Nevertheless, four problems subsist: Hydrogen hot combustion in presence of the

nitrogen of air generates NOx; Hydrogen is a vicious gas for all

material, including steel and lubricant; Hydrogen injector do not make uniform

combustion; And storage density still to be worked out (See the

INTERNATIONAL ACADEMY OF SCIENCE - Hydrogen storage http://www.science.edu/tech/h74002.htm

). This last point is partly covered in an article in Scientific

American of June 2001 exposing that combustion uniformity is the key challenge

in internal combustion IC engine. As a matter of fact, Researchers have been

looking how to make a uniform combustion in Diesel engine (injectors are not

making a uniform combustion) for 40 years. A short summary of problems in

converting conventional engine to hydrogen is given at http://www.greenconcepts.com/producttips/hydrogenfuel/hydrogen02.html

. For all those considerations, the

Quasiturbine is the best of all solutions.

Environmental concerns: Hydrogen and oxygen combustion gives water, only if no other chemical products are present. A problem with a conventional internal combustion (IC) engine running on hydrogen, is that NOx are produced from the air nitrogen (76%), and because they are very toxic pollutants, this causes significant emissions concerns, and present solution by cooling the combustion temperature by excess air mixture further lower the engine power and efficiency. The performing conventional internal combustion IC engines operated on hydrogen may not easily meet the future severe environmental emission standards. Another concern is related to the internal combustion IC engine oil degradation in presence of hydrogen, and the eventual toxic residues safe elimination (not by the exhaust). The Quasiturbine operating on hydrogen has favorable potential emissions characteristics to meet severe standards, because very little NOx are produced, and it has the potential to be an oil-free engine (see the summary of the combustion characteristics below). The Quasiturbine is quite a recent invention, and theoretical emission characteristics of the hydrogen powered Quasiturbine should be validated by measurement testing as soon as possible...

Quasiturbine characteristics and the environmental solution: The Quasiturbine pressure pulse is shorter and increased linearly (as opposed to tangentially at the TDC position like the sine wave of the conventional crankshaft). This means that photo-detonation at the TDC is not followed by a long confinement time, responsible for so many broken pistons. Furthermore, because the pressure pulse is 15 to 30 times shorter at the top dead center, photo-detonation invariably occurs there and the Quasiturbine is not synchronization sensitive, and because compression occurs late after the intake is done, it does not easily backfire (See the INTERNATIONAL ACADEMY OF SCIENCE - Hydrogen combustion and back fire http://www.science.edu/tech/h74001.htm ). The objective is to operate the Quasiturbine in photo-detonation mode, with compression ratio of 20:1 to 40:1 ! (Polluting with piston, but not with the short and linear Quasiturbine pressure pulse). The radiation is then the triggering source of a volumetric combustion, and will occur for all molecules, including hydrogen, methane and others. In fact, the lower the octane index is, the better the combustion will be, because the octane additive are by nature radiation absorbents. To be able to work under photo-detonation mode require other engine characteristics, and the Quasiturbine has all those requirements. No more sparkplug, just crank it. No more diesel injector, just pulverized or mix with atmospheric air intake (unless stratified intake is needed). 500 times less NOx because the Quasiturbine has a confinement time too short to allow for the chemistry of the NOx to occur. No more timing synchronization. Conversion in mechanical energy extends early and late compared to piston engine, and for this reason the combustion gas cools down adiabaticaly (not a thermal lost) faster than in piston engines, such that the heat flow to the engine block is less than with piston, and this is the reason why the second steam cycle is less required in Hydrogen Combined Cycle Quasiturbine HCCQT.

Other Quasiturbine unique characteristics for hydrogen:

Trying to convert a naturally aspirated conventional Internal Combustion IC

engine to naturally aspirated hydrogen poses problems (See http://www.greenconcepts.com/producttips/hydrogenfuel/hydrogen02.html

), because the high inflammability of the hydrogen which tends to

backfire while still in the intake stroke, particularly with 11:1 or higher

compression ratio. The piston chamber gets hot during the combustion and exhaust,

and does not quietly intake hydrogen mixture at intake time. Furthermore, the

piston geometry does not permit good intake stratification where air and

hydrogen can be intaken separately. Rotary engine present a less severe

situation in this regard, because the combustion occurs to the area opposite to

the intake, and intake can be well stratified by using two distinct intake

ports, one on each rotor side. The fact that the Quasiturbine is not sensitive

to photo-detonation and can stand it, makes it very attractive for hydrogen

operation because hydrogen is the ideal photo-detonation fuel! In

the piston engine, oil is required for lubrication but also as internal coolant,

which is giving little incentive for oil-free piston engine. In fact, oil is not

required for the interface of the ring and the piston cylinder, but essential

because of non co-linearity of the piston and the connecting rod, which generate

an ovalization force on the piston against the cylinder which must be well

lubricated. The Quasiturbine does not present such unfortunate parallax effect

and furthermore, the Quasiturbine has no oil-pan and its rotor is also an

external part, so that the rotor and the stator are cooled by air flow, and not

by internal oil spray. Consequently, the Quasiturbine has the potential to be a

true oil-free engine, which is also expected to reduced the viscosity friction

and increase further its efficiency. Finally, piston rings are known to

brake easily under hydrogen atmosphere due to the fact that the external

perimeter of the ring is in tension (not compression) while in presence of

hydrogen, which favors its fragilisation and breakdown. None of the Quasiturbine

seals is in tension, which means a longer seals lifetime.

Why not use an Hydrogen Combined Cycle Quasiturbine HCCQT? Very

high efficiency gas turbine electrical power plants use a Combined Cycle Gas

Turbine CCGT to reach efficiency of about 55% (58 to 60% according to http://www.fossil.energy.gov/techline/tl_ats_ge1.shtml

or http://www.energyusernews.com/eun/cda/articleinformation/coverstory/bnpcoverstoryitem/0,2582,6779,00.html

), because (1) it uses the heat from the gas combustion cycle to turn a turbine

and (2) it uses the residual heat to generate steam for a steam turbine cycle.

These are quite high tech sophisticated pieces of equipment with limited live

span time and further, they are accompanied by high maintenance cost. In the

Quasiturbine power plant, there would be also two cycles. In the first cycle, a

Quasiturbine would be used as an internal combustion hydrogen gas engine to

generate electric power. The sensible heat from the first cycle would then be

run through a heat exchanger to generate steam in a boiler for the second cycle.

Because of similar Quasiturbine's unique ability to run on combusted hydrogen

and steam, in the second cycle, steam would provide a second Quasiturbine's

motive force, thereby increasing overall fuel efficiency. Furthermore, the

Quasiturbine center being empty, the internal combustion (IC) and Steam

Quasiturbines can be on the same shaft, with a simple ratchet coupling, and the

torque will be cumulative on one single electrical generator! The interesting

point (from a capital cost standpoint) is that it does not required two

different systems, as with the natural gas turbine and the steam turbine do with

a CCGT. The Quasiturbines would function as both a hydrogen gas turbine (first

cycle) and as a steam turbine (second cycle). Operationally, it would run the

Quasiturbine in first cycle mode until steam is built up in the boiler. When the

steam pressure is adequate, a computer would start the second Quasiturbine cycle

mode. As steam pressure decreases, the computer would return to the first cycle

mode only. Thus, in principle, one could have a Hydrogen Combined Cycle

Quasiturbine HCCQT. The fuel efficiency of the HCCQT would probably be

less than a true CCGT (55%) but more than the Quasiturbine alone (33%) which can

run at higher internal hydrogen temperature because of early adiabatic expansion

mechanical conversion. This type of efficiency would actually be more than a

fuel cell stack, which, despite some claims to higher efficiency, is only about

35% at most from raw fuel, and quite costly on lifetime maintenance. For

small unit, the combustion cycle could be combined with the

Quasiturbine-Stirling cycle, which with a spoon of water can also work as a

closed circuit steam engine. Details at:

http://quasiturbine.promci.qc.ca/QTStirling.html .

Other Quasiturbine advantages: The Quasiturbine is a very low RPM engine. Internal Combustion IC engine idle is under 200 RPM and up to 3000 or more. It does not required a gearbox to direct drive an electric generator. The Quasiturbine hydrogen gas engine can be made very large to drive 10's of megawatts size generator. Low noise, low tech equipments, low maintenance cost, minimum plant personnel qualification required.

Other markets:

Fuel cells:

Some commercial markets are being the same as the market misappropriately

targeted by fuel cells. Fuel cells, operating on reformed natural gas, will have

very low emissions. Demonstration that an internal combustion IC Hydrogen

Quasiturbine Engine also has low emissions characteristics operating would

provide a low price alternative to fuel cells. For marketing purposes, the

Quasiturbine's more favorable hydrogen emission characteristics will be very

important.

Quasiturbine Pneumatique

et la Pile à Combustible : Un Mariage Parfait (à l'aide

d'azote liquide) !

Voir :

http://quasiturbine.promci.qc.ca/FQTPileCombustible.html

High power density applications:

Generally speaking, the commercial market of natural gas Quasiturbine or CCQT is

not being the same as the market targeted by fuel cells, neither it will the

high power HCCQT Quasiturbines. On the RAGON diagram, the Quasiturbine is the

highest density power plant by weight and volume. Fuel cell chemistry forbids

such a specific high power density (which is very appreciated also in the

transportation industry). The Quasiturbine is such a recent invention, and

already some are not willing to wait longer to test this spectacular high power

density...

Hybrid vehicle:

It is not certain that HCCQT could be practically adapted for a hybrid electric

vehicle. It might depend on the size of the boiler. But if such a

Hydrogen-powered, hybrid electric vehicle could be engineered, it might well

approach the 80 mpg (gasoline equivalent) vehicle that DOE has wanted,

especially with a regenerative braking system. For small units, a Quasiturbine-Stirling

engine could replace advantageously the second stage steam-Quasiturbine.

Distributed power generation:

Another market for HCCQT is distributed power generation and uninterruptible

power supplies. The HCCQT would have fuel efficiency advantages similar to a

CCGT but would be compact enough to be easily located on-site. If the HCCQT

could be sold for about US$800 per kW installed, it could be a cost-effective

option in this market. Because of the multi-fuel capability, the Quasiturbine

seems like an ideal power generator for these applications with hydrogen,

keeping open the multi-fuel option of natural gas, syngas, hythane, etc.

Cogeneration:

The Quasiturbine is quite recent invention, and already some opportunities are

presenting themselves for cogeneration projects.

State of the Quasiturbine technology:

No Quasiturbine has yet run under hydrogen fuel. A new generation of

Quasiturbine engine prototype will be custom manufactured starting in summer

2002, and following testing, they may be available for rent to research labs or

hydrogen involved corporations, by fall 2002 (?)

* * * * *

La Quasiturbine fut absente du

The

WHEC 2002 - 14th World Hydrogen Energy Conference June 9 - 13, 2002 - The

Hydrogen Planet

http://www.hydrogen2002.com

The Conference will be held at The Queen Elizabeth Fairmont Hotel in the great

city of Montréal (Montreal) from June 9th to the 13th, 2002.

This Meeting has been entitled The Hydrogen Planet to

reflect the march towards

the hydrogen economy and the hydrogen infrastructure that will

?

result in a

sustainable clean environment of planet hydrogen.

Organized by the Canadian Hydrogen Association

in collaboration with the US National Hydrogen Association

under the auspices of the International Association for Hydrogen Energy

Link of interest:

Hydrogen Energy Center (HEC) http://www.h2eco.org

Canadian Hydrogen Association (CHA) http://www.h2.ca

US National Hydrogen Association (NHA) http://www.hydrogenus.com

International Association for Hydrogen Energy (IAHE) http://www.iahe.org

* * * * *

Produit en développement.

Seulement des

PROTOTYPES DE RECHERCHE D'USAGES

sont disponibles présentement.

| Retour au menu principal |

Quasiturbine Hydrogène Inc.

Casier 2804, 3535 Ave Papineau, Montréal Québec H2K 4J9 CANADA (514) 527-8484 Fax (514)

527-9530

http://quasiturbine.promci.qc.ca

quasiturbine@promci.qc.ca