Steam is a source of energy, specially in co-generation and geo-thermal...

Steam power is more and more prominent in industry around the world.

Steam Quasiturbine could not come at a better time.

Quasiturbine Steam Engine

Quasiturbine Uniflow Characteristic

In most reciprocating piston engines, the steam reverses its

direction of flow at each stroke (counter-flow). By entering and exhausting the

cylinder by the same port, the cylinder valve and walls are cooled by the

passing exhaust steam, while the hotter incoming admission steam is wasting some

of its energy in restoring the temperature. Some energy is further lost in

reversing the motion momentum of the mass of steam within the piston. The aim of the piston uniflow is to

remedy this defect by providing an exhaust port at the end of the stroke, making

the steam flowing only in one direction, but has the inconvenience of

recompressing some residual cylinder steam. Quasiturbine is a uniflow engine,

with the further advantage of not recompressing any residual steam, resulting in

superior energy efficiency. Recompressing residual steam means some

reversibility losses, and the pressure increases makes a substantial restriction

to the initial steam flow into the chamber, not to ignore the truncated cycle

near bottom dead center - None of this with the Quasiturbine.

Quasiturbine has no vane

Unlike vane pumps, which vane extension is important and against which the pressure acts

to generate the rotation, the Quasiturbine contour seals have an

imperceptible extension and the rotation does not result from pressure against these seals.

The vane geometry does not allow high compression ratio at TDC (top dead center), while Quasiturbine does,

and this is why QT is efficient (less pressure charging losses), and this is why there is no vane combustion engine.

Quasiturbine publishes « efficiency data » while vane motor manufacturers don't. Premium on « efficient equipment »

is rapidely recovered in operational cost...

Mechanical Conversion of Low Heat

From looking at the USA energy flow chart at

http://eed.llnl.gov/flow/02flow.php

The amount of Low temperature heat discarded is quite

impressive. This waste energy has a tremendous potential for energy recovery,

and the Quasiturbine offers more ways to tackle the challenge through Brayton,

Ranking and Stirling cycles!

La pression d'un circuit vapeur est déterminer par le point le plus froid (condensation),

alors que l'éfficacité est donné par la température de la vapeur (les

surchauffeurs font une chauffe à pression constante - celle du point froid,

souvent la chaudière elle-même). L'efficacité optimum requiert souvent un

surchauffeur distinct de la bouilloir, laquelle fixe la pression. Coté

efficacité du cycle lui-même, la basse pression de vapeur réduit la demande de

puissance de la pompe d'alimentation en phase liquide, ce qui est pratique mais

pas critique, parce que du point de vue globale, l'addition d'énergie au système

par la pompe est presque totalement récupérée par la turbine...

Mise à part la chaleur latente, l'énergie est essentiellement dans les débits

volumiques, et les débits en phase liquide sont typiquement 600 fois moindre

qu'en phase vapeur.

Souvent, l'optimum est d'utiliser les thermies basses températures comme

préchauffe d'un cycle à plus haute température, au quel cas l'efficacité

différentielle du carburant utiliser pour la haute température est bonifiée...

La QT favorise un cycle vapeur basse pression aussi pour une raison

réglementaire, car les hautes pressions sont dangeureuses et bien exigentes.

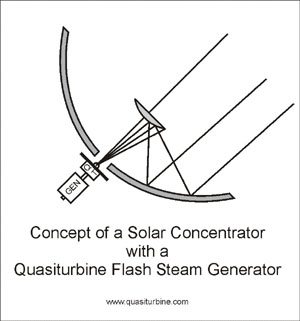

Dans le cas de la QT, nous préconisons pour le solaire, de supprimer la

chaudière, et de chauffer le bloc moteur de la QT lui-même, et d'injecter de la

vapeur gardée en phase liquide dans un injecteur pour vapeur éclaire (flash

steam). Pratique aussi pour les unités mobiles qui craignent les réservoirs

d'eau bouillante.

Quasiturbine Steam

Steam power is staging what may prove to be the

biggest grass-roots comeback in the history of the industrial revolution! From micro-horsepower to

Giga-Watts, from microchips to motorcycles, and from wheel chairs to missions to

mars, STEAM POWER IS BECOMING PROMINENT IN VIRTUALLY EVERY INDUSTRY IN EVERY

COUNTRY OF THE WORLD. Steam Quasiturbine could not be at a better time.

The Quasiturbine steam engine does not produce vibration.

Quasiturbine pneumatic-steam model QT75SC (Without carriage)

Usable with intake sustained pressure as low as 20 to 50 psi!

The Quasiturbine steam engine does not make any vibration.

Approximated first order theoretical steam case with a 33 bars (500 psi)

effective differential pressure

at 1800 RPM without any gearbox. This simplified linear extrapolation does not

guaranty that the steam flow will permit to reach 1800 RPM for the larger units.

Preliminary sizing data for Quasiturbine are as follows (no intake cut off):

| Shaft Power |

Rotor diameter |

Rotor thickness |

| 50 kW (70 HP)

0,4 MW (530 HP)

3 MW (4 000 HP)

25 MW (33 000 HP)

200 MW (260 000 HP)

|

13 cm (5 inches)

25 cm (10 inches)

53 cm (21 inches)

1 m (3,5 feet)

2 m (7 feet)

|

5 cm (2 inches)

10 cm (4 inches)

20 cm (8 inches)

41 cm (16 inches)

82 cm (32 inches)

|

Notice that in 4 strokes internal combustion mode, the

Quasiturbine power is about 1/8 of the one indicated,

increasing almost linearly to this maximum 1800 RPM. Notice that the Quasiturbine power increases

almost linearly with the RPM on a large range.

Remark on Steam Efficiency

An high efficiency steam motor does not guaranty the high

efficiency of the entire steam system. The cooling steam effect during

relaxation must not be under-estimated. For high pressure drop (not allowed with

the prototypes), intermediary heating is a must to keep up the pressure and

avoid condensation. No steam circuit is easy to design and operate.

The

Quasiturbine can further make internal gas expansion if the dominant restriction

is made to be at the intake, such that the flow is not sufficient to keep the

internal pressure at the level of the pressure intake line. This internal

expansion can then be done without any synchronization valve. Efficiency

increases as the involved gas pressure is lower.

Since water requires an important quantity of latent vaporization heat (which

is not generally recovered in the condenser or in the atmosphere open circuit),

operation with saturated steam will always give low efficiency (5 - 10 %)

(unless with a cogeneration application), because of the important volume

of water which needs to be evaporated to maintain the pressure. Even if the

Quasiturbine can accept saturated steam, it is not suitable from the energy

efficiency stand point, that this steam stays saturated during all the cycle. In

fact, in all expansion thermal machine (the Quasiturbine being one of the most

efficient), increase in thermal efficiency is always linked to steam overheating

(without having to increase the pressure), since then one gets the same pressure

effect with less molecules, wherein making a substantial reduction in the

quantity of water needed to be vaporized (... and saving of the

corresponding latent heat energy, while some more calories are lost in the

exhaust). With an important overheating, the efficiency of the thermal steam

engines can reach and even exceed 50% ... (The overheating may occur in the

steam pipes, or in the Quasiturbine itself). In practice, a tuned conventional

system can have an efficiency exceeding 20%, with direct drive and instant

reverse.

From the steam engine point of view, no more need for very high pressure steam to be efficient!

The conventional steam turbines require very high pressure in order to generate the high flow

speed permitting the turbine to be efficient. This is not the case with the

Quasiturbine which is very efficient (engine efficiency, not necessarily the

system efficiency) at all pressures, all load levels and all RPM, and can

produce substantial power with sustained intake pressure as low as 20 to

50 psi and at only 1800 RPM. In those two cases however, the super-heated steam

increases the efficiency of the steam cycle, and the lower pressure operation

may lead to larger equipments for the same power... The Quasiturbine greatly

reduces the station construction and operation cost, reduces substantially the

risk, improves the safety level, and reduces the law constraints and the qualifications

needed from the employees.

For optimum performance, the feed line must be well

balanced between the two intake ports, which must be done by ending the line

passed the 2 T by an accumulator (buffer) tank, on which the pressure gage can

be located.

The Feed Pump is not a net energy lost

Historically, to avoid feed pumps, the steam boiler was over-designed to hold

sufficient water for a full operating cycle. This is still of interest for the

solar steam systems (or geothermal), ou il est avantageux d'avoir une citerne

d'eau pressurisé en marge du circuit vapeur suffisante pour l'alimentation la

journée entière (remplissage la nuit), justement pour ne pas avoir à injecter

les condensats contre la pression de vapeur. Une seconde citerne peut accumuler

les condensats à la sortie de la turbine à pression atmosphérique, et le

transvasage peut se faire la nuit sans soleil... Ici, la pulsation quotidienne

est obligatoire de toute façon.

Coté puissance spécifique, la pulsation du cycle à haute fréquence impose

l'arrêt du circuit vapeur et la chûte de pression de la chaudière (et son

refroidissement en pure perte), un inconvénient majeur qui fait baisser à la

fois la puissance moyenne et l'efficacité thermique. Voilà pourquoi on revient à

la pompe de remplisage en phase liquide et continue! Many think that the feed

pump in a steam (Rankin cycle) is a system waste of energy, while in fact, most

of the feed pump energy is recovered by the turbine. It is like the compression

energy in a piston engine which is almost all recovered at relaxation, or the

energy of the compressor turbine in a Brayton cycle (jet engine), recovered in

the hot turbine.

Adiabatic versus Isothermal

Since the Quasiturbine is a pure expansion engine

(which the Wankel is not, neither most of other rotary engines), it is well

suitable as compressed fluid engine, including steam engine. Like for the pneumatic,

the steam Quasiturbine includes two circuits, these circuits can

be fed in parallel, or in series by connecting the exit of the first

chamber to the entry of second. By placing an exchanger on this conduit one can add heat and

doing so, the total relaxation in the engine approaches an

isothermal relaxation. Notice that in this case, the pressure differential

between the two circuits will be automatically equalized.

In the conventional turbines, such an intermediate heating is often

done in order to increase the total

power of the machine, without necessarily increasing the efficiency. In other

words, to extract the maximum energy from a very high pressure, it

would be necessary to use a cascade of machines starting with the smallest, each one

reducing the pressure a little and feeding the following one through a

heat exchanger... The old steam

engines used up to 3 machines (or more stages in the case of turbines),

the Titanic had steam engines using 4 stages of relaxation... The MDI air

car for its part suggests to use a very high pressure 3 stages piston

engine. Nothing prevents from juxtaposing 3

Quasiturbines of different dimensions to do still better!

Cascade Expansions?

Because the Quasiturbine has 2 independent circuits which can be used in serial,

many could suggest that a single Quasiturbine can acts as a dual equal-size

stages expander with an intermediary heat exchanger (with reduced specific power, unless the intake

pressure is raised). This is not likely to be the case, because the serial

interconnection of the chambers makes the exhaust volume of the first stage to

move into the exact same volume of the intake chamber of the second stage

without making any net additional torque or work (at constant pressure, or even

if an intermediary heat exchanger increases the temperature and the pressure

during the transfer). Because the exhaust and the intake chambers stay at the

same pressure during the transfer, that pressure would not be a constraining

back pressure to the first stage. The final result would be equivalent to give

heat to the exhaust without getting any work out, and would give a neutral role

to the second stage. Characteristics would be similar to the one circuit only

steam mode.

However, experimentation with inter-stages check-valves, intermediary tank, Venturi

pressure phase shift... and super-heater could make it a worth avenue to explore.

The Quasiturbine can further make internal gas expansion if the dominant restriction

is made to be at the intake, such that the flow is not sufficient to keep the

internal pressure at the level of the pressure intake line. This internal

expansion can then be done without any synchronization valve (cut-off intake). Efficiency

increases as the involved gas pressure is lower. The present possibilities have

not yet been tested.

High Temperature Steam

Utilities are the place to find high temperature steam, and the Quasiturbine

is a very interesting option for such an energy station.

Use of superheated steam could be done in one of the

Quasiturbine circuits, while the other circuit could be used to circulate

cooling air (Quasiturbine turbo-pump mode), permitting to extend the

Quasiturbine operation without reaching the material temperature limit.

Co-generation Saturated Steam

The Quasiturbine is an unmatched alternative to saturated steam turbine with

modulated power output.

Geothermal

Like for co-generation, the Quasiturbine Steam is unique for such a low level

thermal source.

Nuclear Steam

Nuclear reactor have very sensitive core and are used to give thermal energy

at almost constant temperature. Temperature level in nuclear power plant are

much less than in coal or heavy fuel station. For this reason, nuclear steam

cannot expand as much before reaching condensation point, and their turbine are

not as efficient. With the Quasiturbine however, full expansion would be

possible to the condensation point, and this would improve the efficiency.

Furthermore, the Quasiturbine can drive a generator without gearbox, one of the

costly element of conventional turbine...

Flash Steam Quasiturbine

In conventional boiler, the heat is capture in large

quantity by the latent liquid evaporation prior overheating, and none is capture

later at relaxation time. By contrast, in flash steam system much less heat is

initially capture while overheating the flow in the liquid phase, but some

additional heat is being capture at the flashing time from the engine bloc. In

both cases, for equivalent power and temperature condition, similar liquid and

heat flows could be involved. To get the most heat transfer in flash steam

system, high pressure maintains a water liquid state into the feed line and

prevent evaporation prior to expansion until it get into the QT, which could be

at a somewhat lower temperature as the heat recovery system may provide heat

gradients. When the steam is released into the QT and expansion takes place, the

pressure of the overheated water is largely reduced and its over-heat is

provided to the latent evaporation, while complementary heat energy is being

captured from the hot engine bloc.

Consider a water feed line pressure of 1000 psia at the saturation temperature

of 544 F. If the water is entering at 100 F, then the liquid temperature rise

would be 544 -100 = 444 degrees F, and about 444 btu per pound of water energy could

be extracted from the source (In one hours time 2545 / 444 = 5.7 lbs of water

per hour per HP. If expansion was to atmospheric pressure, the specific volume

would be would be about 26.8 cu ft per pound, or 26.8 x 7.7 = 206 cu ft per hour

per HP). During the process, the hot engine bloc would provide additional heat

to the expansion. By contrast, allowing the water to boil and evaporate at 1000

psia would capture 3 times more heat (meaning 1/3 of the flow for the same

capture) hg = 1198 btu per pound (Then 2545 / 1198 = 2.1 lbs water per hour per

HP, and expanded to atmospheric pressure, the volume would be 26.8x2.1 = 56 cu

ft water per hour per HP), with an efficiency of the saturated case of about

33%. Flash steam efficiency may not be the best, but

practicability of the system may be much more suitable in mobile applications by

allowing the Quasiturbine to run cooler, without any dangerous pressurized steam

reservoir.

Small Quasiturbine Steam Engines

I - Conventional steam engine - An engine in the boiler!

Because it is an efficient, compact and zero vibration engine, the Quasiturbine

can be located inside the boiler in a very compact and portable way:

II - Hot water injection engine (in-situ evaporation) Flash steam Quasiturbine

Because the Quasiturbine accepts saturated steam,

a positive way to bypass the intake steam flow limitations is

to use the Quasiturbine itself as evaporator.

In this case, the remote boiler becomes a simple hot water tank without evaporator,

and the pressurized hot water taken in a close loop at the base of the tank is brought to

the engine intake,

where droplets of water and oil are directly injected in the expansion chamber,

and consequently evaporated inside the Quasiturbine itself.

In this case, the latent heat of vaporization is also given to the engine by the close

pressurized hot water loop

via a pipe coil enclosing the Quasiturbine.

The exhaust steam goes to a conventional condenser and returns to the boiler.

This option also presents the advantage of requiring a much smaller boiler,

pipes of small dimensions, miniature control valves,

and permits potentially to reach higher rotational speed.

In the case of thermal solar systems, if the internal liquid reserve is large enough for

all the sunshine period,

this operation mode needs only one unique fill up at night !

III - Cold water injection engine

This mode would definitively be unimaginable with conventional turbine, since they react to the speed of steam flow,

which must be pre-conditioned. In fact, if a burner heats the Quasiturbine engine bloc directly, there is no

need of a boiler any more

(The Quasiturbine acting simultaneously as the boiler, the over heater and the evaporator),

and one can then inject cold water (which will be preheated in the injector)

at a pressure superior to the internal maximum working pressure.

Ideal mode for thermal solar concentrator heating directly the Quasiturbine engine bloc !

(This mode is equivalent of using the Quasiturbine engine bloc as a "flash steam generator")

(Notice that a remote heat source could use an un-evaporating fluid like oil or

liquid sodium to transfer heat to the engine bloc).

Because pressure steam only exist for a short time and only

within the chamber (no steam boiler), this alternative is one of the safest in

term of blowing-up, and as potential to avoid most pressure product legislations

and rules, which is today a serious steam project handicap (no qualified steam

expert needed for operation!).

IV - Quasiturbine Stirling and Short Steam Circuit

This is also a way to make an interesting compact portable engine as described on the Stirling page

quasiturbine.promci.qc.ca/ETypeStirling.htm

V - Quasiturbine Brayton Short Air Circuit

Flashing steam into a Hot Quasiturbine is a Ranking cycle (phase change

requiring a liquid pressure pump), but injecting cold compressed air into a Hot

Quasiturbine and letting it expands is like < flashing AIR >, and this is a

short circuit Brayton QT cycle. Similarly to the Ranking which need a liquid

pressure pump for intake, this Brayton cycle would need an external cold air (QT

?) compressor (Notice that the energy given to the compressor is not lost, but

recovered as pushing pressure during the flashing process).

Rotary Pressure Regulator

What about an "energy recovery rotary pressure regulator" ?

An interesting application of the steam Quasiturbine is to recover the high pressure energy at

pressure reduction stations. Instead of using a conventional cooling station,

a steam Quasiturbine will rotate under the

pressure differential and the flow will be controlled by the rpm, i.e. the

torque applied on the Quasiturbine shaft. This way, the Quasiturbine can

transform the pressure differential into useful mechanical work to run pump,

compressor, ventilator, electricity

generator or locally convert the energy in high grade heat. Because

conventional turbines can not be widely modulated in rpm and load, they are not

suitable for gas flow and pressure control, while the Quasiturbine is

essentially a closed valve at zero rpm, and has high efficiency at all torque

and all flow rpm. All experimental demonstration has to be done only by steam

experts and under all current rules and regulations.

Other Steam Applications

Apart from conventional uses as for electric production, marine or locomotive

propulsion, here some interesting steam applications:

Engine Exhaust Heat Recovery:

By placing a hot Quasiturbine into or around an engine exhaust pipe, and

injecting pressurized hot water (steam keep in the liquid state for better heat

transfer), some heat can be recovered into mechanical energy! Same technology could apply to:

Industrial exhaust gases heat recovery

industrial furnace heat recovery

Industrial process heat recovery

Chimney or stack heat recovery

Waste heat recovery

Solar heat recovery

Geothermal heat recovery

Thermal nuclear heat

Solar thermal plant:

Because the Quasiturbine is efficient at different output level, it is most

suitable for modulated power output as solar thermal plant. Direct solar heating

of the Quasiturbine steam is also a major feature for solar concentrator

plant... Be aware that the technical literature contains a lot of statement

referring to system feed pump or piston compression cycle, as a lost of energy:

this is not true, piston compression cycle energy is mostly recovered during

relaxation, as the feed pump energy increases the system output accordingly...

The intermediary reflector can be suppressed

by moving the power pack inward, and heating the QT on the peripheral.

Steam pressure reduction station:

A Quasiturbine placed on a steam line can act like a volumetric governor

according to the power that one extracted from it, and doing so, it acts

like a station of reduction of steam pressure for the various stages of

the industrial processes, without having to cool the steam, remove the

heat, or lose a lot of energy...

Pumping steam-water condensate:

A Quasiturbine used in turbo-pump mode is particularly adapted to pump the

condensed steam (condensate) from pressure steam injection in only one of the

2 circuits of Quasiturbine turbo-pump.

Steam Purge energy recovery:

As the boiler of the industrial steam networks cannot be

modulated quickly in power, these boilers often produce a "steam

supplement" to satisfy the fluctuations of demand which can reach 5 to 10%

of the total capacity. When the demand does not require this

supplement, it is generally purged in total lost. However, the use of one

or several Quasiturbines Steam at the point of purging could allow to

recover a part of the energy to produce by intermittency

compressed air or electricity...

Steam Engine Lubrication

Periodic oil spray needs to be injected into all

engine intakes steam flow. Standard product recommendations start at steam

pressures of 150 to 200 psig (366 to 388 F). The grade of recommended steam

cylinder oil for these conditions is ISO 460 which contains 4% tallow oil.

This is the grade of oil that the “ride-on” locomotive community uses. It

is generally available in 55 gallon drums, but Sulphur Springs Steam

Models sales@sssmodels.com

provides it in quart cans. Chevron USA has a relatively new steam cylinder

oil on the market that is lighter in viscosity than ISO 460 by about half

(1103 SUS vs. 2335 SUS @ 100 F). Other steam oil may do as well. It does

not require much oil, and large steam units generally use a separator in

the condenser, and recycle this oil.

More Technical

Quasiturbine steam

A White Paper

Engine Exhaust Heat Recovery with Quasiturbines

Offering Essential Efficiency Characteristics

Why is the

Quasiturbine revolutionizing the use of steam and solar energy?

Quasiturbine Stirling and Short

steam circuit

The

Steam-Powered Quasiturbine in Direct-Drive

Railway Locomotive Propulsion

Quasiturbine - Comparative efficiency

with other engines

International Association for the Advancement of Steam Power

The

Quasiturbine is

listed with INIS © International Atomic Energy Agency

|