Consider the Quasiturbine burning

hydrogen with its

stratification intake, low detonation sensitivity and oil free potential.

Consider also advanced detonation hydrogen combustion mode...

Quasiturbine Hydrogen Type

March 2003 - MIT study says

Improving gasoline and diesel engines is the way to go!

Hydrogen car is no environmental panacea. The hydrogen fuel-cell vehicle will not be better

in terms of total energy use and greenhouse gas emissions by 2020.

If we need to curb greenhouse gases,

improving mainstream gasoline and diesel engines is the way to go.

These results come from an assessment of a variety

of engine and fuel technologies forecasting no real 'breakthroughs'.

(The Quasiturbine having been excluded from the study)

Hydrogen: Not Zero Pollution

Excludes NOx and H2S environmental concerns. Fossil fuel contains carbon and hydrogen. Carbon

combustion produces CO2 which the photosynthesis fixes the carbon into the

biomass, and return the O2 to the atmosphere. Hydrogen combustion

fixes the O2 from the air into water, which oxygen is also liberated back

in the atmosphere by photosynthesis. Since there is not enough

photosynthesis to digest all the CO2, there is not enough either do

process all this synthetic water. Massive hydrogen use has the net effect

of removing oxygen from the atmosphere of our planet and fixing it into

water. CO2 problem is not dissociable from Oxygen depletion. Hydrogen

produced from water (avoiding electrolyses degradation of precious

electricity) will do the same if the oxygen is not liberated to the

atmosphere at the time of production, which is unlikely, considering that

oxygen is precious for industrial process and will rather be fixed by

other chemical process, unless we could not make use of all the massive

quantity produced?

As a result, unless oxygen is made free to the

atmosphere when produce, we can not say that transforming hydrogen

into water vapor (including by combustion or fuel cells) is pollution

free, when 2H does definitively removed

1 precious oxygen atom form the

surface of our planet! (some calculation

show

this is not an issue, but?). Both CO2 and oxygen depletion are

concerns. Synthetic fuel made out of CO2 from the air or

other environment would be more neutral and acceptable - However,

where will the energy to do that come from?

Hydrogen Sources

There is no molecular

hydrogen on the planet Earth, we need to make it!

Energy transformation from one source to another is costly in all terms.

About 10% of the crude oil is consumed to refine gasoline, but up to 35% is

consumed to make methanol.

Transforming fossil fuel in electricity has not been done very efficiently in

the past,

even if new technologies are making substantial progress into the 60% efficiency

range. Fossil fuel to hydrogen has similar lost. Why transforming fossil

fuel-into-hydrogen with such a lost?

Water is the end result of hydrogen combustion. In term of

energy, water is like burned hydrocarbon or ash. The energy content of water is

so minimal that no other liquid is better to extinguish fire! Making hydrogen

fuel from water is energetically the same as making gasoline back from the

exhaust gases (CO2 and water). Transforming precious electricity from fossil

fuel is a severe energy degradation which should not be permitted? (one would get

more hydrogen by swapping its electricity on the world market).

Solar and bio-transformation may be part of the solution

for moderate volume.

The objective is generally to take the pollution (and the poor efficiency) away

from the end users,

but what is the net gain, and at what cost? Environmental human and planet

issues about massive hydrogen production are still open and quite questionable.

Energy transformation is never a good idea. Producing

hydrogen from fossil hydrocarbons means a lost of up to 30 % of initial

energy. Then, to store the hydrogen gas is also expensive in energy of

compression often lost during the relaxation. Following one decade

exploratory on hydrogen, one will rediscover soon that the best way to

store hydrogen is to bind it all around a carbon atom CH4, C3H6...

to form (synthetic if coming from nuclear energy?) gases liquefiable or liquids that one

call hydro- (for hydrogen) -carbon fuel. We will soon rediscover that we

are already within an hydrogen economy, with effective and not so dangerous

hydrocarbon fuel! Sure there is a place for hydrogen and fuel

cells, but not intelligently everywhere... If we have energy available, lets

make synthetic fuel instead of gaseous hydrogen!

Hydrogen or synthetic fuel, the Quasiturbine will not

make much of a difference as it is an exceptional engine for both...

Hydrogen Storage in Carbon Molecules

A good way to store hydrogen is to link it with carbon atom.

This can produce either gaseous, liquid or solid

high energy density products most convenient

for transportation and mobile uses.

When needed, just heat up those carbon-hydrogen molecules,

and the hydrogen will liberate.

For energy production, the hydrogen storage in carbon molecules

is forward and most efficient, because in presence of oxygen,

not only the hydrogen separates and burn producing water vapor

(a so low energy contained product, that it is used in fire extinguisher),

but the carbon atoms will also burn, first in CO

(which has about the specific thermal energy content

of the hydrogen), and which can further burn into CO2.

(also a low energy contained product used in fire extinguisher).

You win twice !

Other hydrogen storage techniques do not seem to be as practical.

This hydrogen carbon molecule storage technique is safe and simple,

and has been appreciated by humans for centuries,

under the name of hydrocarbon fuels !

GM and BMW are taking different routes on the road :

- GM has invested heavily in developing fuel cells

to power electric motors in vehicles,

replacing the current internal combustion engines.

- BMW, on the other hand, is studying burning hydrogen

in internal combustion engines as a more practical alternative.

Internal combustion engine are combined hydrocarbon fuels

"hydrogen extractor and mechanical converter" all at once !

... and the Quasiturbine is most appropriate to do just that in vehicles

Environmental Concerns

Hydrogen and oxygen

combustion gives water, only if no other chemical products are present. A problem

with a conventional internal combustion (IC) engine running on hydrogen,

is that NOx are produced from the air nitrogen (76%), and because they are

very toxic pollutants, this causes significant emissions concerns, and present

solution by cooling the combustion temperature by excess air mixture further

lower the engine power and efficiency. The performing conventional internal

combustion IC engines operated on hydrogen may not easily

meet the future severe environmental emission standards without sophisticated

exhaust treatment. Another concern is

related to the internal combustion IC engine oil degradation in presence of

hydrogen, and the eventual toxic residues safe elimination (not by the exhaust).

Quasiturbine

The Quasiturbine operating on hydrogen has favorable potential emissions

characteristics to meet severe standards, because very little NOx are produced

due to its shorter volume pulse, and because it has the potential to be an

oil-free engine, while having optimum efficiency.

Liquid versus Gaseous Fuel

Ultimately, all fuels get into gaseous state in engine combustion chamber, so one

may be at first legitimate to expect little difference with liquid fuel,

but looking at the combustion process itself is not where the answer stands.

One needs to look at the details of the specific engine intake and dynamic.

Because engines generally prefer a near stochiometric mixture

(except for non-homogeneous Diesel and homogeneous detonation, which both works

in excess of air),

the amount of fuel and air have to be balanced at intake. Lets consider the

gasoline 4 strokes piston engine.

When the intake valve opens, a fix volume is aspirated.

Since the gasoline intaked as liquid droplets does occupy a negligible volume,

most air available can be intaken from the depressurized intake manifold.

In this regard, the gasoline injectors near intake valves are superior to the

carburetors

in permitting more liquid droplets and less gasoline atomization (vapor),

which explains why the modern gasoline injector engines have a higher specific

power density.

Fortunately with the piston engine, when the intake valve closes, there is

plenty of time for the gasoline droplet to atomize

during compression and later even during the combustion stroke,

because optimum pressure is not required until well pass the TDC (top dead

centre).

However, this droplets intake technique is not without adverse effect on

pollution,

but this slow imperfect combustion saves the engine valves from being torched

out!

By opposition, intaking gaseous fuel which occupied a substantial volume, will

leave less volume available for air intake,

and the engine specific power density will be diminished.

To make it short, it is not easy to produce the same combustion condition by intaking liquid or gaseous fuel,

and those condition differences are further apparent in the front flame velocity

(in addition to the specific chemistry characteristics...).

Because of its continuous intake flow and its early and late intake

characteristics,

the Quasiturbine is most able to minimize the gaseous fuel intake penalty.

Detonation - A Must for Hydrogen

In order to do work on a piston, the fuel-air mixture needs to burn at

a speed faster than the piston is moving. The following discussion exclude

hydrogen detonation, which is much different from combustion.

At stoichiometric ratio (no air nitrogen?), hydrogen (uncertain H2

and O2 mixture, with HHO ?) flame speed has been reported up to 3.46 m/s

[11.35 feet/second] which would be nearly an order of magnitude slower

than gasoline 40 m/s [from 70 up to 170 feet/second],

and at lean mixture, the hydrogen flame velocity decreases

significantly. However, engine experts are not

working in stockiometric condition but report

hydrogen-air mixture flame front speed and gasoline-air mixture flame

front speed accordingly.

Stochiometric is an ideal situation which does not occure in IC.

With gasoline, engine do not run exactly stochiometric mainly to

preserve the exhaust valve from overheating, and

to reduce NOx production. Quite the same with

hydrogen in combustion engine. Difference in

comparison is also with the mixture power density because hydrogen is a

gas with a low power density. Per pound hydrogen is more powerful but at

atmospheric density, hydrogen is less powerful compare to gasoline

mixture. Matter may still be open to discussion,

but lower hydrogen flame speed observed in IC engine condition is a

disadvantage shared with most other gaseous fuels. This is why a

detonation capable engine is so important to overcome these limitations.

Source: Mark's Standard Handbook for Mechanical Engineers, Section

9, Internal Combustion Engines, Flame Speed, more at

www.mb-soft.com/public2/hydrogen.html

An average vehicle engine rotating at 2,000 rpm (33 revolutions per

second) produces piston linear speed of 45 feet/second in the

middle-stroke, which is already 5 times faster than the hydrogen flame

front speed ! The fact that a hydrogen-air mixture has a flame front speed

of about 1/10 that of a gasoline-air mixture contributes to explain why

hydrogen engines only run at reduced power and low rpm under load.

However, the detonation mode is extremely rapid and totally removes this

limitation to hydrogen. This is why the detonation mode (not compatible

with piston, but with the Quasiturbine) is somewhat critical for the

future of the hydrogen engine.

Where does the Quasiturbine detonation mode

stands?

Everyone has experienced that lens sun focalization can lit a fire.

As the compression ratio of an engine increases, not only the gas temperature

increases, but also the radiation level.

Combustion goes primarily through at least 3 processes while the compression

increases:

- Primo, at low compression ratio, a hot spot (spark) is required to start a

combustion front flame wave.

This subsonic wave propagates and lits progressively the mixture (this is smooth

deflagration use in our gasoline vehicle).

- Secundo, higher pressure will provoke thermo-ignition, which is a very

non-uniform process liting mixture patches,

and inter-patches combustion being driven +/- by the previous describe front

flame wave.

- Tertio, still higher compression ratio produces uniform radiation driven liting

process,

which is an extremely rapid volumetric combustion (supersonic).

In this case, there is essentially no front propagation, just a powerful light

radiation everywhere...

This last one is the most severe knocking that the piston cannot stand, but it is the

most powerful and perfect way to combust fuel!

In fact, additives used to increase the gasoline octane index

are efficient photon absorbents molecules which prevent this kind of photons

build-up,

and such polluting additives are not needed in detonation mode engine.

Even if shock waves do have the potential to lit a fuel mixture,

photo-detonation does not actually make use of a shock wave within the mixture.

However, the rapid chamber pressure increase does generate a shock wave in the

engine environment,

which could be substantially moderated by a rapid increase of the combustion

volume at that TDC time

(this is what the Quasiturbine does!).

So, why does the piston don't stand the photo-detonation ?

Because it stands high compression near TDC (top dead center) much too long

before producing useful work at mid-stroke.

And why does the Quasiturbine stand it (particularly the QTAC model) ?

Because the volume pulse is 15 to 30 times shorter near TDC, and also because

its higher surface to volume ratio

is moderating the violence of the detonation process, which is almost

independent of the mixture front-wave flame velocity...

Consequently, even if the Quasiturbine can run in conventional Otto mode,

its photo-detonation mode provides the most benefit to fuel efficiency and

environment, both for liquid or gaseous fuel...

Fuel Cell

The Best Current present state hydrogen technologies:

Fuel cells, operating on reformed natural gas, will have very low emissions, but

despite some claims of very high efficiency, their efficiency is at most about 35%

from raw fuel, and half of that in small portable electric motor units (efficiency

falls when getting near maximum output power). Furthermore, they are not readily

available for high power output plants yet nowadays, and they are far from

matching the Combined Cycle Gas Turbine CCGT efficiency, which reaches about

55%. Cost and internal contamination are also limitations.

Finally, if breakthroughs are still expected with fuel cells,

the detonation internal combustion is also

an expected breakthrough with internal combustion engine

which could save half the fuel now consumed in gasoline vehicles

with substantial environment benefits.

Quasiturbine and Hydrogen

Hydrogen is not easily usable in conventional internal combustion IC engine

due to its high inflammability and lower atmospheric pressure specific energy

(30 to 50 % power drop), and generally does require sophisticated and costly synchronized

gas injectors. However, the IC efficiency is potentially competitive.

Nevertheless, four problems subsist: Hydrogen hot combustion in presence of the

nitrogen of air generates NOx; Hydrogen is a vicious gas for all material,

including steel and lubricant; Hydrogen injector does not make uniform combustion;

and storage density still to be worked out.

Quasiturbine characteristics and the environmental

solution: The Quasiturbine pressure pulse is shorter and increases

linearly (as opposed to tangentially at the TDC position like the sine wave of

the conventional crankshaft). This means that detonation at the TDC is not

followed by a long confinement time, responsible for so many broken pistons.

Furthermore, because the pressure pulse is 15 to 30 times shorter at the top

dead center, detonation invariably occurs there and the Quasiturbine is not

synchronization sensitive, and because compression occurs late after the intake

is done, it does not easily backfire. The Quasiturbine geometry allows for

separate intake of air and hydrogen (stratification), low detonation sensitivity

and oil free potential are other favorable hydrogen characteristics.

The fuel cell chemistry will not permit

to make very high density power plant in weight and volume

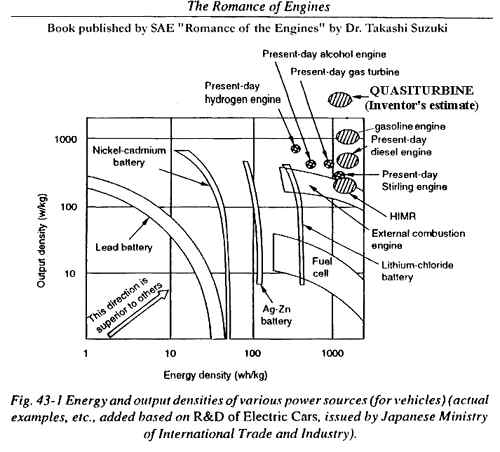

as shown on this RAGON engine diagram,

like it is easily done with internal combustion (IC) engine.

For many applications from chainsaws or motorcycles, to propeller airplanes,

hydrogen and multi-fuel internal combustion engine will then be most suitable anyway.

The piston

chamber gets hot during the combustion and exhaust, and does not quietly intake

hydrogen mixture at intake time. Furthermore, the piston geometry does not permit good intake

stratification where air and hydrogen can be intaken separately. Rotary engine

presents a less severe situation in this regard, because the combustion occurs to

the area opposite to the intake, and intake can be well stratified by using two

distinct intake ports, one on each rotor side. The fact that the Quasiturbine is

not sensitive to detonation and can stand it, makes it very attractive for

hydrogen operation because hydrogen is the ideal detonation fuel!

In the piston engine, oil is required

for lubrication but also as internal coolant, which is giving little incentive

for oil-free piston engine. In fact, oil is not required for the interface of

the ring and the piston cylinder, but essential because of non co-linearity of

the piston and the connecting rod, which generates an ovalization force on the

piston against the cylinder which must be well lubricated. The Quasiturbine does

not present such unfortunate parallax effect and furthermore, the Quasiturbine

has no oil-pan and its rotor is also an external part, so that the rotor and the

stator are cooled by air flow, and not by internal oil spray. Consequently, the

Quasiturbine has the potential to be a true oil-free engine, which is also expected

to reduce the viscosity friction and increase further its efficiency.

Finally, piston rings are known to brake easily under hydrogen atmosphere due

to the fact that the external perimeter of the ring is in

tension (not compression) while in presence of hydrogen, which favors its fragilisation and

breakdown. None of the Quasiturbine seals is in tension, which means a longer

seals lifetime.

Quasiturbine Hydrogen Markets

The Quasiturbine has the quality to best fit the direct hydrogen combustion

engine. However, the Quasiturbine can have other roles as well in an hydrogen

economy:

Fuel cells:

Some Quasiturbine commercial markets are the same as the market

targeted by fuel cells. Fuel cells operating on reformed natural gas,

will have very low emissions. Demonstration that an internal combustion IC

Hydrogen Quasiturbine Engine also has low emissions characteristics would

provide a low price alternative to fuel cells.

Quasiturbine Pneumatic and Fuel cell :

A perfect Match (using liquid nitrogen) is also quite

an interesting application.

High power density applications:

Generally speaking, the commercial market of natural gas Quasiturbine is

not the same as the market targeted by fuel cells, neither will the

high power Quasiturbines. On the RAGON diagram, the Quasiturbine is the

highest density power plant by weight and volume. Fuel cell chemistry forbids

such a specific high power density (which is very appreciated in the

transportation industry).

Hybrid vehicle:

Hydrogen Quasiturbine generator could be practically adapted to hybrid electric

vehicle. But if such a hydrogen-powered,

hybrid electric vehicle could be engineered, it might well approach the 80 mpg

(gasoline equivalent). For small units, a Quasiturbine Stirling engine could

replace advantageously the second stage for thermal recovery.

Distributed power generation:

Another market for hydrogen Quasiturbine is distributed power generation and

uninterruptible power supplies. It would have fuel efficiency advantages similar

to gas turbine but would be compact enough to be easily located on-site. It could be a cost-effective

option in this market. Because of the multi-fuel capability, the Quasiturbine

seems like an ideal power generator for these applications with hydrogen,

keeping open the multi-fuel option of natural gas, syngas, hythane, etc.

Cogeneration:

The Quasiturbine has an optimum efficiency in a wide range of power output,

which makes it unique for power modulated cogeneration projects.

State of the Quasiturbine hydrogen engine:

No Quasiturbine has yet run under hydrogen fuel. A new generation of

Quasiturbine engine prototypes will be custom made in due time for this purpose.

More Technical...

March 2003 - MIT Engine Recommendation Study

Fuel cells and pneumatic Quasiturbine: A perfect match!

Quasiturbine for vehicles

Hydrogen Energy Center (HEC) http://www.h2eco.org

Canadian Hydrogen Association (CHA) http://www.h2.ca

US National Hydrogen Association (NHA) http://www.hydrogenus.com

International Association for Hydrogen Energy (IAHE) http://www.iahe.org

|