Engine Technology International Magazine

distributed to over 12,000 powertrain designers worldwide

www.ukintpress.com/mag_engine.htm

The magazine hosts the annual International Engine of the Year

award

http://www.ukintpress.com/engineoftheyear/

The magazine hosts the annual

Engine-Expo, in Stuttgart Messe, Germany

www.engine-expo.com

September 2006

Quasiturbine: Unusual Engines - Turbine Tale

by Brian Cowan in « Engine Technology International » Magazine

* * * Text File * * * Quasiturbine:

Page 58

UNUSUAL ENGINES Turbine tale

by

Brian Cowan

How a family in Canada is working hard to deliver the next radical breakthrough in internal combustion engine design

■ Will the automotive industry ever again be graced with new, radical designs when it comes to the development of internal combustion engines? Many would say no – after all, so many clever people have tried fruitlessly for so many years to develop a better layout than the orthodox reciprocating piston and crankshaft. Surely every possibility, no matter how fanciful, must have already been canvassed in this powertrain development area? Well, so you’d think; but the past few years have, if anything, seen an upsurge in the numbers of ingenious new engine designs. For that, we must partly thank the ready availability of advanced digital design tools. As ever, though, the stumbling blocks to wider industry acceptance lie in the details of performance, fuel consumption, emissions, and long-term reliability. A century and a quarter of continuous development means that the status quo has a decent head start and a newcomer would have to show an improvement in at least one specific area to be taken seriously. Of the newest crop, one that stands out for its boldness of concept and the way it addresses some of the fundamental handicaps of both the piston

Page 61

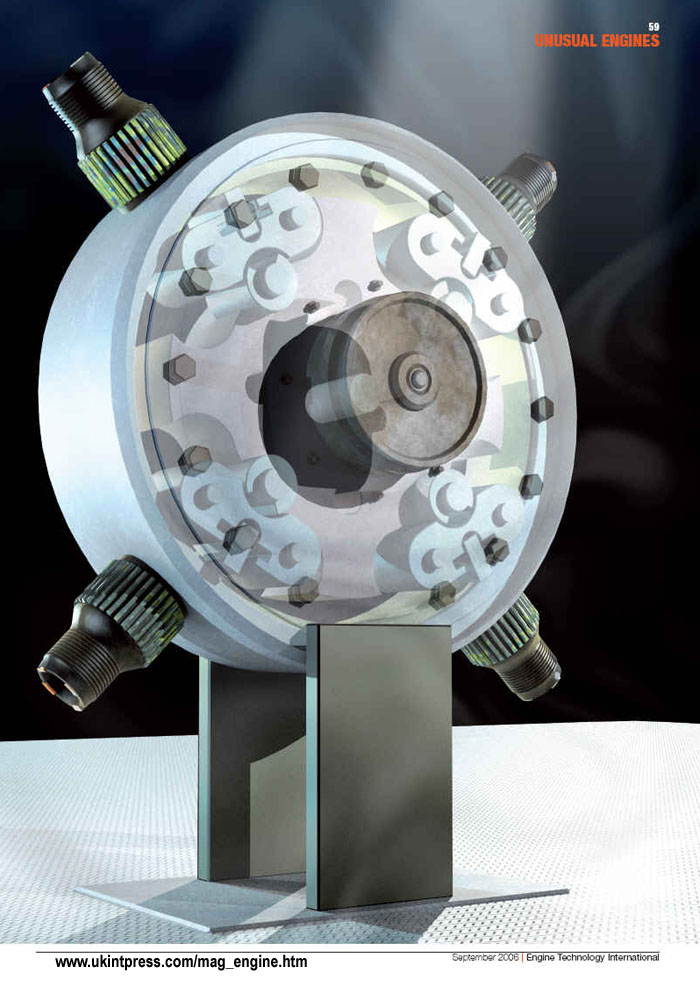

ICE and the Wankel rotary is called the Quasiturbine. Developed by a family of Canadian researchers – Gilles and Françoise Saint-Hilaire and their sons Roxan and Ylian – the Quasiturbine has superficial similarities to the Wankel, but as its name implies, is closer to a turbine, despite not having the conventional curved blades. The Wankel connection derives from the housing in which the operating blades turn, which is not circular but, at a glance, shares characteristics with the epitrochoid of the Wankel. However, it is a simpler shape than that, being an oval roughly like an athletics running track – or an ice-skating rink, which is the analogy the Saint-Hilaires prefer. The turbine allusion derives from the fact that – operating as an internal combustion engine – the design provides almost continuous power impulses, in contrast with the one in four strokes of a standard four-stroke piston. Another turbine-like characteristic is the virtual absence of out-of balance forces: At all times, the center of mass of the Quasiturbine’s rotating parts remains on its center line, in contrast to the eccentric motion of the Wankel rotor as it spins around on its fixed sideplate gear to generate its cylinder geometry. In its simplest form, the Quasiturbine rotor comprises four equal length links, jointed at their ends and turning freely inside the casing. The combination alternately forms a square or lozenge shape within the housing, providing the compression and expansion phases of a four-stroke Otto cycle. During one rotation of the links, four full combustion cycles are completed. A more complex approach to the basic Quasiturbine principle can be taken with a design that uses wheeled carriages pivoted at their center on the joints between

“As its name implies, the Quasiturbine is closer in principle to a turbine than a Wankel”

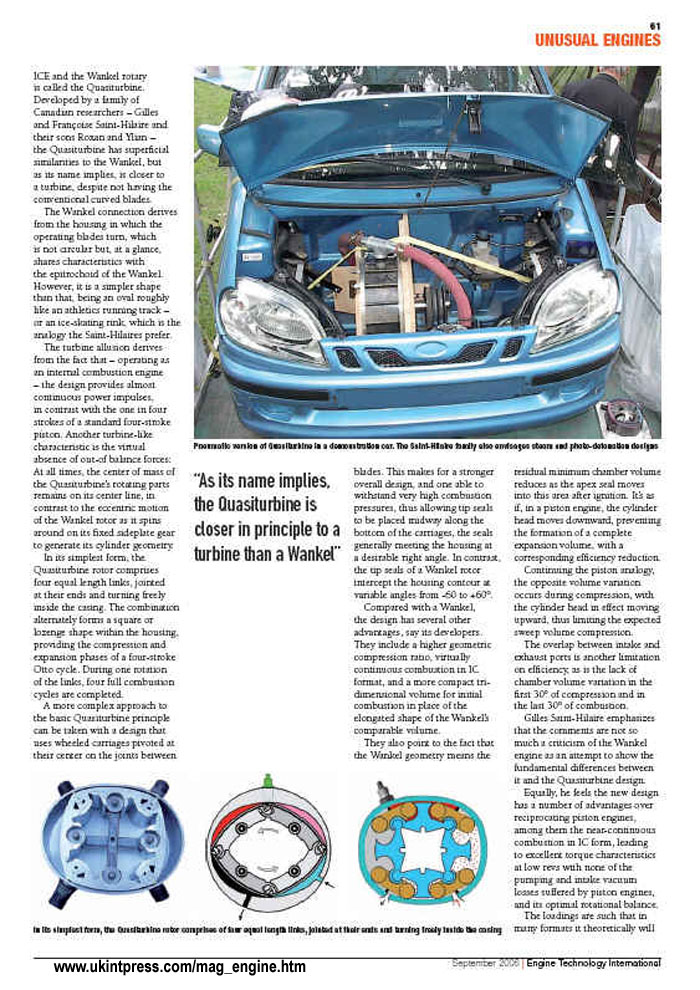

(Photo Car)

Pneumatic version of Quasiturbine in a demonstration car. The Saint-Hilaire family also envisages steam and photo-detonation designs

(Photo Quasiturbine)

In its simplest form, the Quasiturbine rotor comprises of four equal length links, jointed at their ends and turning freely inside the casing

blades. This makes for a stronger overall design, and one able to withstand very high combustion pressures, thus allowing tip seals to be placed midway along the bottom of the carriages, the seals generally meeting the housing at a desirable right angle. In contrast, the tip seals of a Wankel rotor intercept the housing contour at variable angles from -60 to +60°. Compared with a Wankel, the design has several other advantages, say its developers. They include a higher geometric compression ratio, virtually continuous combustion in IC format, and a more compact tridimensional volume for initial combustion in place of the elongated shape of the Wankel’s comparable volume. They also point to the fact that the Wankel geometry means the residual minimum chamber volume reduces as the apex seal moves into this area after ignition. It’s as if, in a piston engine, the cylinder head moves downward, preventing the formation of a complete expansion volume, with a corresponding efficiency reduction. Continuing the piston analogy, the opposite volume variation occurs during compression, with the cylinder head in effect moving upward, thus limiting the expected sweep volume compression. The overlap between intake and exhaust ports is another limitation on efficiency, as is the lack of chamber volume variation in the first 30° of compression and in the last 30° of combustion. Gilles Saint-Hilaire emphasizes that the comments are not so much a criticism of the Wankel engine as an attempt to show the fundamental differences between it and the Quasiturbine design. Equally, he feels the new design has a number of advantages over reciprocating piston engines, among them the near-continuous combustion in IC form, leading to excellent torque characteristics at low revs with none of the pumping and intake vacuum losses suffered by piston engines, and its optimal rotational balance. The loadings are such that in many formats it theoretically will

Page 62

require no supporting central shaft, with the tip joints of the linked rotor plates being simply guided by the chamber contour. Higher output applications can use a stator ring and bearing shafts fitted to a sideplate. Drive take-off is through the center points of the blades, which describe a circular path because of the alternating square-lozenge shape of the assembly that’s at a constant tangential velocity. Several different power transmission mechanisms are envisaged, among them a cross linked framework, or a differential type drive with the blade centers being linked alternately to a pair of adjoining annular rings. This drive system highlights another plus for the Quasiturbine concept, in that it is largely empty along its center line, leaving room for the likes of electrical components and making for a compact overall size. Nor is it limited to internal combustion applications, for it lends itself equally to steam, pneumatic, or hydraulic drive, or as a compressor. Depending on application, intake and outlet ports can be placed either around the periphery of the housing or through the sideplates. Despite the geometry of the Quasiturbine chamber looking superficially simpler than a Wankel’s epitrochoid shape, the calculation of the contour family of curves for the design incorporating carriages is quite complex, depending primarily on the distance between wheel axes, wheel diameter and carriage height. The rocking motion of the carriages, which tends to fill the combustion chamber volume, means the carriages can be constructed to provide a fearsomely high effective compression ratio. This, say the Saint-Hilaires, makes the design ideal for photo-detonation (HCCI), triggered by a spike on the P-V diagram, for all the world like a cursive letter ‘i’. The design is robust enough to handle the pressure spike, but because of the spike’s brevity and the rapidity of the subsequent expansion phase, the overall combustion temperature is lower than in a conventional engine, thus reducing the formation of oxides of nitrogen. Because of the sequential nature of the combustion phases, a new cycle can be triggered by a channel on the chamber periphery that allows hot gas from the adjoining expansion phase to bleed back into the combustion area. That scenario is the ultimate application of the design, says Gilles Saint-Hilaire. Aware of the time and massive financial investment needed to integrate such a radical concept into transportation technology, he sees his company’s efforts in the short term being directed more toward commercial applications involving pneumatic drive – things like lightweight chainsaws and scrub cutters, or in pump and compressor layouts. “Engine integration is a vast domain in which we would prefer not to get involved at this time,” he said recently, “because it limits our role as engine supplier. Consequently, just like the early years of piston engines, our first step is with pneumatic and steam engines. They will be followed by Otto-cycle internal combustion engines and ultimately by a photo-detonation design.” Two models of pre-commercial prototypes (pneumatic and steam) have been developed for sale or lease – the smaller with a total intake volume of 600cc per revolution, its twice-dimensioned partner displacing 4.8-liters. A prototype of the smaller unit has also been developed for a chainsaw application. The bigger model is usable with a pressure differential as low as 1.4 to 3.4 bar. Applying 2.8 bar to the intake produces a torque of 1,355 N-m (correction: 1,355 x 3 x 40 = 160 N-m) and output of 8 bhp (correction: about 12-15 bhp) at 500 rpm – a fraction of the unit’s potential peak power, says the firm. Several combustion prototypes have been tested, but their development is less advanced. The Quasiturbine’s inventors seem to have few illusions about the long road ahead before it is integrated with a vehicle, but they are supremely confident of the basic principles of the design. In answer to the thought that the time has passed for any form of internal combustion engine, Gilles Saint-Hilaire says that as technologies like photo-detonation engines begin to emerge in the marketplace, the trend away from internal combustion may start to reverse itself. After all, he says, small engines with the efficiency of a large utility station completely eliminate the need for storing electrical energy by producing clean power on demand.

(Inventer photo)

“Our first step is with pneumatic and steam engines, followed by some Otto-cycle ICEs”

RENAISSANCE FAMILY?

The Saint-Hilaire family packs a formidable level of intellectual firepower, along with expertise in diverse practical fields. Father Gilles (left) is a thermonuclear physicist who has worked in environmental and renewable energy research. Son Roxan has an electrical engineering degree and works in the US on ultra-fast image transfer devices; his brother, Ylian, has a masters in computer science and is a designer of computer chips. Both have worked with their father on project Quasiturbine. Françoise Saint-Hilaire, the boys’ mother, has a master’s degree in literature from the Sorbonne (Paris). She contributes to all major decisions and handles the administrative organization of the company. Gilles and his two sons all hold multi-engined commercial pilots’ licences. The genesis of the Quasiturbine design came during a two-year family sabbatical aboard a sailing yacht in the late 1980s when Gilles became frustrated by the unreliability and inefficiency of small capacity engines – in outboards, generators, air compressors, and the like. He initially looked at a small conventional turbine design to supplant them, but over time developed the linked plate turbine theory that is behind the Quasiturbine.

www.ukintpress.com/mag_engine.htm Engine Technology International | September 2006