|

|

New technology progresses a step at a

time.

Internal Combustion Quasiturbine

(Otto, Diesel or Detonation)

are not yet disclosed

No unit is for sale at this time

Many readers are impatient to know more

about the IC Quasiturbine.

For this reason, an engine comparison methodology is presented here,

which could be adapted to individual potential reference piston engine.

THEORETICAL METHODOLOGY OF COMPARISON:

DIESEL PISTON ENGINE

VERSUS

DIESEL QUASITURBINE

Comparison Generalities

In any comparison, the Quasiturbine will not likely

simultaneously match the torque, the rpm and the power at its optimum

regime, in part because of the two different engine geometries, and

because of constraints related to combustion consideration (the Wankel nor

the conventional

gas turbine can match all piston characteristics at once). At

design, for the same power, a high torque QT has large diameter and short

thickness, while a higher rpm QT design has a smaller diameter and a

greater thickness (this is the QT "diameter to thickness ratio" analogue

to the piston crankshaft diameter). At this time we keep with the QT600

convenient diameter to thickness ratio.

For a simultaneous optimum operation match, no piston

combustion similarity constraints must be imposed and an appropriate QT

ratio should be selected at design. Let detail below two basis of

comparison:

A - Matching The Power

B - Matching the Combustion Conditions

C - Comparison Summary

Reference Diesel Engine

There is a vast choice of engines on the market which

could be referred to in the context of this theoretical comparison (which

is in no way intended to discredit any fine piston technology - Could

rather be an honor?). Because the powerful diesel engines are the most

critical to the industrial world, let's

pick-up arbitrary the:

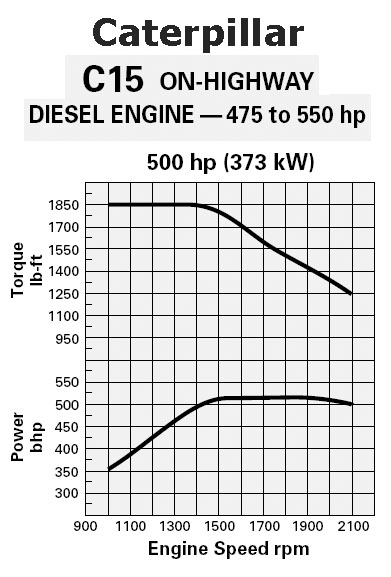

Caterpillar Turbo charge C15 15.2L Heavy-Duty Engine

as described by the manufacturer at

http://ohe.cat.com/cda/layout?m=85523&x=7

http://ohe.cat.com/cda/files/209038/7/C15.pdf

Specifications:

4 stroke turbo 6 Cylinders In-Line

Bore/Stroke 5.4 x 6.75 (137mm x 171mm)

Displacement 15.2 L (928 cu in)

Weight 2890 lb (1311 kg)

Horsepower 435 to 625 @ 2100 rpm

Torque 1550-2050 lb-ft @ 1200 rpm

For comparison, let's consider a single operation point approximated from the graph as

follow:

Torque 1600 lb-ft;

Revolution 1600 rpm;

Power 500 HP.

A - Matching the Power

Because both piston and QT are displacement

engines, a way to make a first approximation comparison is by matching the

displacement volume flow (power) within both types of engine.

Turbo Cat Flow = 0,5 x 15 liters displacement engine x 1600 rpm = 12000

liters/min

(0,5 because the 4 strokes piston takes 2 revolutions to intake the displacement

volume, it does intake 7,5 liters per revolution). Turbo Cat internal average

net added piston pressure can be estimated from the torque Net Added pressure =

torque / (1 piston surface x (3/2 simultaneous piston) x crankshaft radius) (ignore sine form

factor, about the same as QT-SC).

Turbo Cat Net Added Pressure = 165 psi effective

Turbo QT600SC

As a guess, an equivalent combustion QT600SC

would theoretically give 3,3 lb-ft / psi

(this is the peak torque during a combustion to match the sine form factor

ignored with the piston), so that 165 psi effective internal combustion pressure

increase (ignore sine form factor) would provide 550 lb-ft torque.

To produce 500 HP with this torque, QT revolution will have to be 5000 rpm

(Not necessarily the optimum regime of the QT?).

The displacement volume flow for this QT would be

Turbo QT600SC Flow = 0,6 liters per chamber x 4 chambers per revolution x

5000 rpm = 12000 liters/min

the same as the piston Cat engine running at 1600 rpm.

Present all steel QT600SC prototypes weight about 150 pounds, light material

could eventually get it down to 50 pounds (?), accessories excluded (the

difference partly results from the absence of QT crankshaft and smaller size).

Notice: No comparison is perfect - Here both engines have the same power. The

volume of the combustion chamber of the piston (2,53 liters) is 4.2 times larger

than the QT600SC chamber volume (0,600 liter). The piston stroke duration at

1600 rpm is 6 times longer than the QT stroke at 5000 rpm (too high rpm ?). This

is an important limitation to this comparison - See Matching Combustion

Conditions below.

Turbo QT5SC

If one doubles all the dimensions of a QT600SC,

he gets a Turbo QT5SC (5 liters chamber; Rotor 22 inches in diameter by 8 inches

thickness) in which the torque (26,4 lbs-ft / psi peak torque) would be 550 x 2

x 2 x 2 = 4400 lb-ft. To produce 500 HP with this torque, QT revolution will

have to be 600 rpm (most realistic, but not necessarily the optimum regime of

the QT?). The displacement volume flow for this QT5SC would be

Turbo QT5SC Flow = 5 liters par chamber x 4 chambers per revolution x 600

rpm = 12000 liters/min

the same as the piston Cat engine running at 1600 rpm.

All steel QT5SC weight would be about 1200 pounds, light material could

eventually get it down to 500 pounds (?), accessories excluded (the difference

partly results from the absence of QT crankshaft and smaller size).

Notice: No comparison is perfect - Here both engines have the same power. The

volume of the combustion chamber of the piston (2,53 liters) is half that of the

QT5SC chamber volume (5 liters). The piston stroke duration at 1600 rpm is 3/4

shorter than the QT stroke at 600 rpm. This is an important limitation to this

comparison - See Matching Combustion Conditions below.

B - Matching the Combustion Conditions

Turbo QT2,53litersSC

Because the conditions of combustion vary with rpm,

volume and torque, a significantly more realistic way to make a

Quasiturbine comparison is to match the combustion chamber volume,

pressure and power stroke duration.

The Piston chamber volume of 2,53 liters defines a new QT2,53litersSC.

Internal effective combustion pressure for both engine = 165 psi

Piston power stroke duration = 1/2 of one revolution at 1600 rpm

QT2,53litersSC power stroke duration = 1/4 of one revolution

QT2,53litersSC rpm must be 800 rpm for the same stroke duration, which implies:

The piston combustion frequency is 3 fires (half the cylinders) per

revolution

The QT2,53litersSC combustion frequency is 4 fires per revolution

In one minute, the piston fires 1600 x 3 = 4800 times. QT fires 800 x 4 =

3200 times

which explains the difference of power output in this comparison.

* Under such a condition, the power of both engines will not be the same.

Cat flow displacement is 12000 liters / min,

QT2,53litersSC flow is = 2.53 liters x 4 x 800 rpm = 8100 liters /

min

* Cat Torque is 1600 lb-ft

QT2,53litersSC torque can be extrapolate linearly from the QT600SC chamber

volume:

QT2,53litersSC torque (pressure = 165 psi) = (2,53 / 0,600) T(QT600SC) =

4.22 x 3,3 lb-ft/psi x 165 psi = 2300 lb-ft

Sizes would be 1,62 time the sizes of the QT600SC.

* Cat power is 500 HP

QT2,53litersSC power at 165 psi and 800 rpm is = 350 HP (lower power with

higher torque) (power is less due to a lower fires frequency: 350 HP x

4800 / 3200 = 500 HP)

All steel QT2,53litersSC prototypes would weight (never been built) about

650 pounds,

light material could eventually get it down to 200 pounds (?), accessories

excluded (the difference partly results from the absence of QT crankshaft

and smaller size).

Turbo QT2,53litersSC-Dynamic

Preservation of the "chamber volume and the stroke

duration (rpm)" fixes the flow

QT2,53litersSC flow = 2.53 liters x 4 x 800 rpm = 8100 liters / min

corresponding to 350 HP, independently of the QT "diameter to thickness

ratio". The piston-QT geometry differences do not allow a power match

while preserving those 2 values. Notice however that this reduced power

would match the one of a 4 cylinders similar piston engine. To match the 500 HP piston power (flow of

12000 liters / min), the QT chamber must be increased in size, or the

stroke duration shorten (rpm increased). This is simply a matter of

particular geometry engine sizes and regime as the parameters "chamber

volume, stroke duration (rpm) and power" are all linked together.

If a perfect match between those 2 technologies is not generally possible, the

dynamic conditions can be optimized by further adjusting at design the QT

"diameter to thickness ratio". While assuming a constant internal pressure

of 165 psi effective, same rpm, and while keeping the power at 350 HP, the

QT2,53litersSC-Dynamic could have a different diameter (larger or

smaller); to preserve the chamber volume of 2,53 liters, its thickness

needs to be inversely modified by the square of the diameter reduced /

enlarged ratio. This will preserve the same torque, but will provide a

different dynamic of the QT. Similar dynamic consideration is given to the

piston engine when selecting the crankshaft diameter.

If the optimum piston power coincides or not with the Quasiturbine optimum

running conditions, it is an other matter... Weight (never been built) would

be about the same as the QT2,53litersSC, but the sizes will take a

different shape.

C - Comparison Summary

The piston reference engine is the

Caterpillar turbo change C15 15.2L Heavy-Duty Engine

http://ohe.cat.com/cda/layout?m=85523&x=7

http://ohe.cat.com/cda/files/209038/7/C15.pdf

| |

Piston Ref.

(Cat C15 15.2L) |

QT600SC |

QT5SC |

QT2,53litersSC

(Matches

chamber

and stroke) |

| Type |

Turbo

4 stroke |

Turbo

4 stroke |

Turbo

4 stroke |

Turbo

4 stroke |

Chamber

volume

(liters) |

2,5

(3 x / rev.) |

0,6 (4 x /rev.) |

5,0 (4 x /rev.) |

2,5

(4 x / rev.) |

Stroke

duration

(sec) |

60/(1600 x 2) =

0,0188 |

60/(5000 x 4) =

0,003 |

60/(600 x 4) =

0,025 |

60/(800 x 4) =

0,0188 |

Engine

combustion

frequency

(/min) |

4800 |

20000 |

2400 |

3200 |

Internal

effective added

pressure

(psi) |

165 |

165

(questionable?) |

165 |

165 |

Revolution

(rpm) |

1600 |

5000

(off limit?) |

600 |

800 |

Torque

(lb-ft) |

1600 |

550 |

4400 |

2300 |

Power

(HP) |

500 |

500 |

500 |

350 |

Outside sizes

(inches) |

- |

diam. 16

thickness 5 |

diam. 32

thickness 10 |

diam. 26

thickness 8,1 |

Weight

/ optimized

(pounds) |

2900

with

accessories |

150

/ 50

+accessories |

1200

/ 500

+accessories |

650

/ 200

+accessories |

| Comment |

6 cylinders

piston versus

4 chambers QT |

Small QT

requiring

too

high rpm |

Large QT

with

lower rpm |

Would match

power of

the 4 cylinders

(not the 6 cyl.) |

If the "chamber volume and stroke duration" constraints are removed, it is

likely possible to design a QT making a perfect match in power, torque and

rpm with most piston engines within a reasonable QT operating range.

However, this match will not necessarily be at the optimum QT operating

conditions...

Of course, 2 or 3 QT could be stacked side by side (like pistons are) to

produce more torque and power. Charging compressor and Stirling exhaust

heat recovery could one day also be of Quasiturbine type!

For the same pressure, steam and pneumatic QT provide more torque and

power density because they use simultaneously 2 chambers circuits, and

keep peak power all along the stroke. QT-AC provides still more power

density due to the plateau shape of its pressure pulse.

Comparison Limitations

This is an approximated theoretical comparison. There

is no actual experimental data to confirming all of the above, so please

allow reasonable safety factor in all interpretations...

More Technical

Quasiturbine - Piston Differences

|

|