Pneumatic is used everywhere: It is safe,

needs little maintenance, last long...

Quasiturbine

Pneumatic Chainsaw

Efficient

Low rpm High Torque

QT.6LSC air motor

This product will be

available

only when homologated for security and environment.

It is the buyer and/or operator

responsibility

to comply with all applicable national

and local laws and rules,

including those on security and pressurized products.

COMPLETE and RUNNING !

Sales (when homologated for security and environment.)

for ? euro (or US$ in America

NAFTA).

Product Description

This chainsaw is shown only as a sample of 1.5

kW QT engine application.

The chainsaw is not available for sale at

this time.

The Quasiturbine chainsaw has been developed to an advance

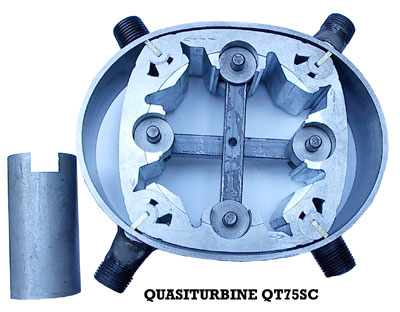

stage. Casing and rotor weight have not yet been optimized (cylindrical outside measurement are about 7 7/8" in

diameter and 2 1/2" in thickness excluding peripherals). It has a total 600 cc intake

volume per revolution. The QT.6LSC has been extensively developed and tested.

Quasiturbine QT.6LSC Pneumatic Chainsaw

Usable with intake sustained pressure as low as 20 to 50 psi!

Several HP on a 60 psi air line.

The rotor and the cylindrical external casing are built of

high metal (no aluminum at this time). Comprise a cylindrical stator bloc, a rotor

and an 3/4-inch diameter shaft throughout. 2 intake ports 1/2"

male NPT pipe threads and 2 exhaust ports 1/2"

male NPT pipe threads. Maximum peak: 60 psi. Periodic lubrication required.

Ideal for mining industries and other environment sensitive applications.

Quasiturbine QT.6LSC Pneumatic

shown without the differential and the central shaft.

A volume of 75 cc per chamber

and the swept volume is 8 chambers per revolution

(4 on the top, 4 on the bottom) which totalized 600 cc per revolution.

At 500 RPM, this is a volumetric flow of 0,3 cubic meter per minute at intake!

Steam - Hydraulic Notice

This is a pneumatic Chainsaw which could be made available

in Steam Quasiturbine option. For this reason, the pneumatic unit must be

running cold, and no steam operation should be attempted. Steam and

pneumatic version must not be used with incompressible fluid (liquid

hydraulic mode) without having been first modified to deal with seals

hydraulic lock.

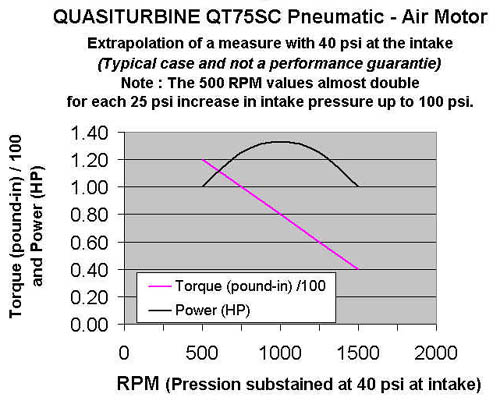

Typical Characteristics

Typical value given as indication only. May vary from one QT to another.

In the present state of development, one needs to typically apply 10-15 psi

at the intake pressure gauge to obtain a free rotation at 500 RPM.

To produce 1 HP at 500 RPM (not the maximum power),

one needs to apply about 40 psi at the intake pressure

gauge.

The "effective differential internal pressure" is then about 25 psi,

producing a torque of 120 pound-inch.

Approxamative torque curve

Model QT.6LSC Pneumatic

(Rotor average diam. 6 in. by 2 in. thickness)

The values vary linearly around this low pressure

point

but must not be inconsiderably extrapolated to high pressures

(Near 1 HP by 25 psi effective, at 500 RPM).

Remark on Pneumatic Efficiency

An high efficiency pneumatic motor does not guaranty the high efficiency of

the entire pneumatic system. All gas heat up during compression and cool down

during relaxation. The cooling effect must not be under-estimate. As an example,

a typical 200 bar (atm.) cylinder empty adiabatically (without thermalization to

ambient temperature) gives at the end an air so cold that its volume is then a

1/4 of that of the air once back to the ambient temperature (isothermal

relaxation). In those temperature conditions at the entrance of a pneumatic

motor, the efficiency is catastrophically low and the lubricant solidified,

which increases considerably the internal engine friction... Generally, the

reversibility of the "compression - relaxation" cycle reduces with an increase in

pressure, which favors for high efficiency consideration the use of the lowest

design pressure possible. The measurement of the exhaust temperature gives

generally a good indication of the efficiency, since the minimum of energy lost

into the environment correspond to an exhaust temperature equal (neither

inferior, nor superior) to the ambient temperature. This condition can be

achieve by a slight heating (solar) of the gas before its entry into the

pneumatic motor. Since the Quasiturbine rotates from pressure as low as 1/10 of

atmosphere (bar) (one psi !), one understand why the Quasiturbine is so well

adapted to high efficiency system... For higher pressure drop (not suitable with the

prototype), an intake air heating coil in hot water would be necessary to prevent freezing of the

oil within the Quasiturbine.

Safety Precautions

-

It is the buyer and/or operator

responsibility

to comply with all applicable national

and local laws and rules,

including those on security and pressurized products.

-

These prototype must be use under the

constant supervision of qualified professional.

-

Never exceed the limits and suggested conditions of operation.

-

Wearing safety glasses, mask and fastened hair is recommended.

-

The demonstration room must be well ventilated.

-

Check the tightening of the bolts and adapters.

-

Be aware of the rupture

or the decoupling of any of the flexible hoses.

-

Have a distant valve at hand to cut the air/nitrogen flow as needed.

-

Always remain vigilant and careful!

QUASITURBINE TRONÇONNEUSES

Manufacturer under a privileged QT-Rotors supply license

agreement

Casier/Code/Porte 2804, 3535 Ave Papineau, Montréal Québec H2K 4J9 CANADA

(514) 527-8484 Fax (514) 527-8484

Associated website www.quasiturbine.com

info@quasiturbine.com

Subject to changes without notice - December 17, 2004

|